Rakesh Suresh

Well-known member

- Joined

- Sep 5, 2024

- Messages

- 110

Funny thing happened. While connecting the probes, the pins touching ENCA and ENCB got shorted and I got check ev system light and wheels did not move. I guess this is expected?

I installed Shotcut yesterday, to build a visual aid in communicating a time-sensitive set of events to a Github project, and the learning curve is thrashing me ATM.@alflash Irrelevant question for this forum, but a quick one. What tools you use to create these videos that you post on Youtube

Depending on the list of purposes and goals of creating a video, I use different sets of video editors.For example, Movavi, Clipchamp, Camtasia and several more AI editors and AI generators "text in photo" and "text in video".@alflash Irrelevant question for this forum, but a quick one. What tools you use to create these videos that you post on Youtube

I do not consider the verification complete because there are still questions (for example, point 1).Now that we have wrapped up the speed sensor testing, I have a few questions about what more could be done to diagnose the heater issue.

1. I think the only test I am yet to do is test with exactly at 40Hz PWM. (I have tested at 4Hz and 100Hz). Is it really necessary to have a 50% duty cycle pwm? if 100% duty cycle is a valid state, could tying RMI to ground a valid test?

Note. The electric control circuits of the heater groups (IGBTs, it drivers, controller, etc.) are galvanically separated/isolated from the input control signal (optocouplers), 12V power supply and GND of vehicle.2. Can I connect probes to components on the PCB for further testing? We would expect the IGBTs to output HV PWM correct? Would connecting a lead to IGBT terminal and HV negative a useful test to do?

It is possible to measure the current from the HV battery using the program, there are current clamps that fix the zero point before measuring in the absence of current.3. There seems to be a Hall effect current sensor where I can connect leads to. Would that help at all?

I. We are currently examining two features/faults described in your measurement results.4. In your image it appears that the peak voltage of PWM of heater control signal is close to 12V. Any other tests I could do to investigate why my heater control signal has a very small peak voltage?

Probably not.p.5. Also immediately preceeding the failure of heater, the GoM had dropped to ~70miles for a few months even when heater was off. However, after the heater stopped working GoM went back to usual ranges. Is there any way to correlate this symptom?

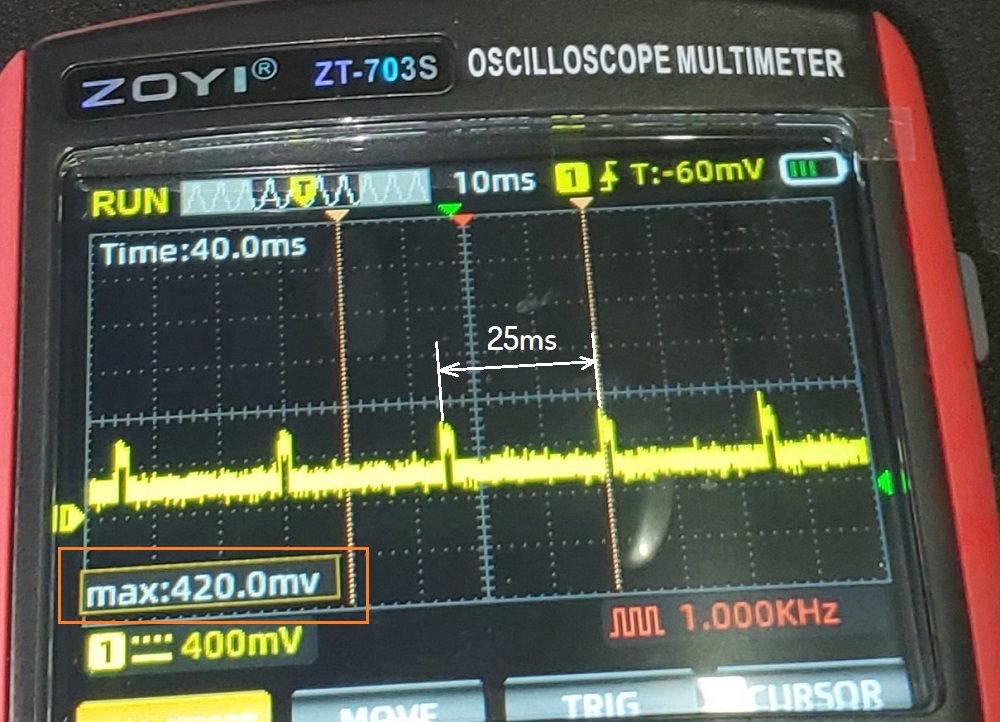

I repeated the test with 40Hz and heater got warm !!In this image (attach.1) we can see that the pulse repetition frequency of the simulator is approximately 40 Hz.B) Use any pulse duty cycle in the range from 20% (max T) to 80% min T).C) I do not know the result of connecting the RMI input to GND. And I would be satisfied with only checking the heater current (according to the program data) when connecting to it (pin RMI) a pulse signal with different duty cycle values (20 ÷ 80%) of the simulator pulses with a frequency of 40 Hz.

Excellent!I repeated the test with 40Hz and heater got warm !!

(To get to 40khz I had to carefully configure the potentiometers without turning it too far and use the lower part of second jumper setting)

I see intermittent 2-3A draw using the clamp meter. The right part of the Aluminum block took significantly longer to heat up than the left part. Not sure if this is expected.

I forgot to take a video if it. It was fluctuating between 1-4A. I have disconnected the 555 pwm generator. Would you like to see a photo/video of it?Current data from TDS about HV Battery Current?

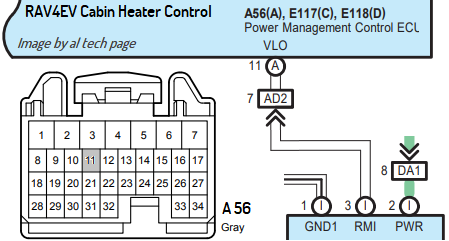

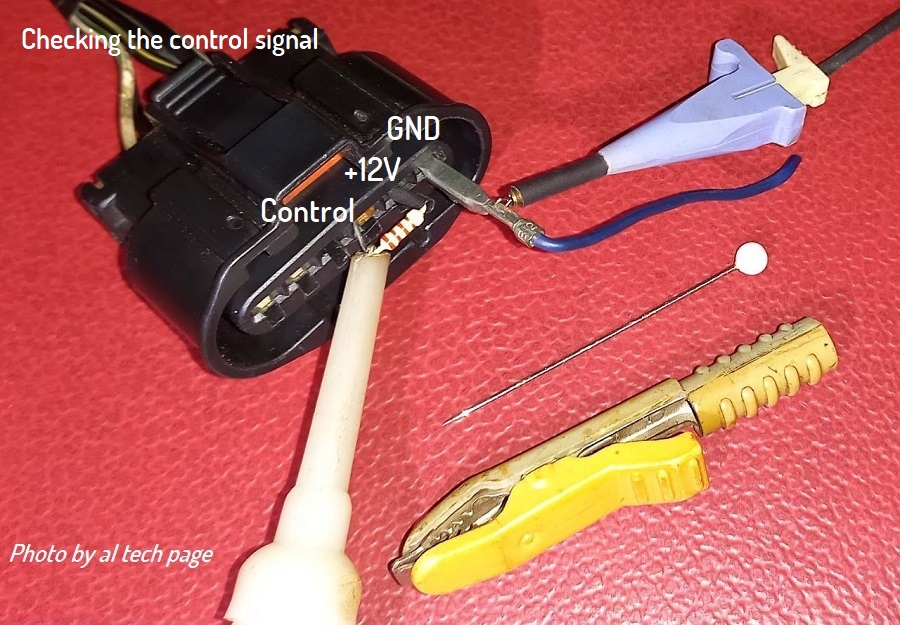

Without connecting d15 - no heater control signalCheck this signal on the wiring connector without connecting to its counterpart with the cabin heating on.

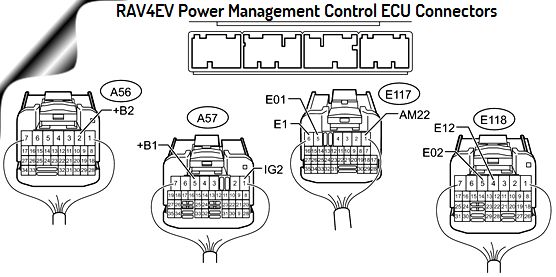

Where exactly is this?Perhaps it will be necessary to deal with the Power Management Control ECU unit.

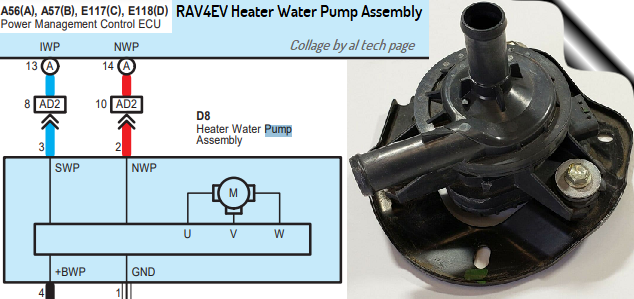

How exactly would I know if the pump turns on? I dont hear a continuous buzz like a usual pump, but some intermittent noise is there when heater is turned on.It is imperative to reliably double-check whether the pump turns on when the cabin heating is turned on.

Oh, there was some noise just before the wheels started to move? I had just ignored this noise thinking that it was because the car being jacked up. Is it something to be concerned about? Any thoughts on why it may be happening?Have you noticed that at the end of the video, against the background of the "Proximity" sound

Wohoo ! Congrats and thanks for all the help !Today is the 7th anniversary of my diagnostics of the first RAV4EV

Thanks...

Where exactly is this?

...

Wohoo ! Congrats and thanks for all the help !

Before this, you need to make sure that the cabin heater is fully functional and is not the cause of very, very small pulses on the RMI contact.Also, can I close the heater assembly? Do you foresee needing to do any more testing on the heater itself? I wanted to start driving the car.

Because this pump is so easily accessed, if you can't tell it's running by putting your hand on it and feeling a vibration, you can use a stethoscope (such as this):How exactly would I know if the pump turns on?

RedRecord (under hood) and "show" the noise you are talking about.

A completely reliable, but not the easiest way is to check the pump control signal and the feedback signal with an oscilloscope*.

I definitely hear some repetitive noise but I don't know if that's how a pump functioning normally would sound.Because this pump is so easily accessed, if you can't tell it's running by putting your hand on it and feeling a vibration, you can use a stethoscope

The sounds are a bit strange, especially the amplitude modulation with a frequency of several hertz. But it seems that the pump is working.I definitely hear some repetitive noise but I don't know if that's how a pump functioning normally would sound.

There is no liquid in the systemIs there liquid in the system?

Oops. I must have run it dry cumulatively for over 30 mins to do all the tests.Most liquid pumps are not rated for operation without liquid. Some pumps' seals can be ruined in seconds when run dry. These pumps don't have friction seals, so that's not an issue for them, but their bearing will probably not appreciate being run dry for any appreciable time!