You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My turn for the Check EV message

- Thread starter user 8087

- Start date

Help Support Toyota Rav4 EV Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I still having the same issue. i have checked all wiring from the sensor all the way to the inverter board and everything seems to be fine. No coolant found at any part of the motor/inverter. I'm wondering if the HV reset(like Doug said on post #27) could be the fix but since i have took apart all the motor i can not install the HV fuse. @asavage Could you please try to disconnect the 12v battery then disconect the HV fuse also disconect the low voltage connector from the inverter side, wait for a night and put it back together, and test if the issue still going.

View attachment 954View attachment 955

View attachment 954View attachment 955

Last edited:

The BMS resides inside the HV battery pack's case and it externally powered by the 12v system. Disconnecting the 12v battery is the only "reset" of the BMS available outside of TPD functions.

The Service Disconnect on top of the HV battery (accessible via the floor, under the right seat) splits the battery modules' circuit in half, and that's all it does (well, it interrupts the HVIL loop, too). Removing it doesn't have any effect to reset anything. It's in series with the contactors, which are open 95% of the life of the battery.

For those reasons, I'm not going to try what you ask, as disconnecting the 12v battery + removing the HV battery Service Disconnect cannot affect the LDU's inverter communications in the way you imagine.

The Service Disconnect on top of the HV battery (accessible via the floor, under the right seat) splits the battery modules' circuit in half, and that's all it does (well, it interrupts the HVIL loop, too). Removing it doesn't have any effect to reset anything. It's in series with the contactors, which are open 95% of the life of the battery.

For those reasons, I'm not going to try what you ask, as disconnecting the 12v battery + removing the HV battery Service Disconnect cannot affect the LDU's inverter communications in the way you imagine.

Last edited:

You are right the HV disconnect is unnecessary. Did you try to disconnect the 12v for a long period of time? I haven’t and I could not try that now because I have the motor remove.. What I have tried is to disconnect and connect the low voltage connector from the side of the inverter and didn’t work.

OK, I've disconnected the 12v battery; I'll check back with it in a day or two and see if it continues to malfunction, and report back.

I had the 12v battery disconnected for >2 days. I just reconnected it, and then I drove up and down my 35' (~10m) driveway at short full-accel bursts, and it errored and opened contactors on the ninth run.Did you try to disconnect the 12v for a long period of time?

$16.06

$16.91

MICTUNING Upgraded Dual USB Port 6.4A QC3.0 Quick Charger with Blue LED Digital Voltmeter Replacement for Toyota, Compatible with Cellphone iPad PDA Laptop GPS (Surface Size 1.6 x 0.9 inches)

Nado Stuff (Authorized Dealer)

$129.99

MAXLINER Floor Mats 2 Row Liner Set Black for 2006-2012 Toyota RAV4 Without 3rd Row Seat

smartliner-usa

I'll be reinstalling the HV battery pack into my blue RAV4 EV next week. It needed to have the contactors replaced, the battery dehumidifier air pump replaced, and I took the opportunity to run some 50mm² shielded HV cabling from the area in front of the HV battery, to the rear bumper area (temporary storage). After that battery is reinstalled, that will free up the table lift that I will use to remove the white RAV4 EV's LDU (the subject of this thread), and I will likely duplicate your efforts.

Hi,

I finally received the parts, coolant delete cap and driveshaft seals, coolant cap installed following this video.

Unfortunately removing and re-soldering the connector did not work. It worked perfectly the first time for an hour switching from D to B and reverse but the next day it worked fine for about 10 minutes and the same error again.

I am not sure if there is another faulty soldering on another component or if there is some kind of reset when I leave it without 12v for a long time and it works fine the first time. I am wondering if replacing the main board with this one on eBay and reflashing it with the tool will fix this problem. This board is very expensive for me, US$550 and I don't want to spend this amount if I am not sure if it will work for sure.

In the meantime I am leaving the car without 12v just to check if this is the reason it worked fine the first time.

Any feedback will be greatly appreciated.

I finally received the parts, coolant delete cap and driveshaft seals, coolant cap installed following this video.

Unfortunately removing and re-soldering the connector did not work. It worked perfectly the first time for an hour switching from D to B and reverse but the next day it worked fine for about 10 minutes and the same error again.

I am not sure if there is another faulty soldering on another component or if there is some kind of reset when I leave it without 12v for a long time and it works fine the first time. I am wondering if replacing the main board with this one on eBay and reflashing it with the tool will fix this problem. This board is very expensive for me, US$550 and I don't want to spend this amount if I am not sure if it will work for sure.

In the meantime I am leaving the car without 12v just to check if this is the reason it worked fine the first time.

Any feedback will be greatly appreciated.

Hi,

I wanted to tell you that something unusual happened. I left the 12V battery disconnected and connected it again yesterday. At first, it worked for a few minutes and then stopped, so the 12v reset didn't work. I decided to measure the sensor, and although I don't have an oscilloscope, I measured one side, rotated, measured again and repeated the process. The voltage on each channel was at 5v and then dropped when turning the shaft; it seemed that the sensor was fine.

Then I thought about measuring it in motion, since it is a square signal, it should show approximately half the voltage on each channel while it is running, and indeed it was around 2.5V on each channel. Before turning it on for the test in motion, I decided to push the low voltage connector of the inverter (where the signal from this sensor comes in) to make sure there was no false contact. The second time I turned it on after moving the connector, it worked for two hours. I turned it off, turned it back on, and it worked fine for another 10 minutes; I turned it off, turned it back on, and it worked for 20 minutes.

I tried it this morning, and it failed after 3 minutes. I pushed the connector back in, and it's been working for about 45 minutes now.

I think it might be a problem with one of these two connectors or the wire that goes to them. I had previously checked the internal connector, and although the solder joints looked bad, and I got a bad continuity reading at first, when I tried to confirm the bad continuity, it no longer showed continuity faults, so I ruled out that it was bad. Also, since the connector is covered in a transparent soft gel, re-soldering it is not easy, so I assumed it was good.

Long story short, sensor voltages are ok, i suspect the connector on the image is bad. Even on this image that is for an item on sale the welds looks extremly bad like mine.

@asavage After your car failed, turn it off and then could you please try to unplug then plug again(or just push it) the low voltage connector the one on that is near of the high voltage cables on the DI. then turn it on and test it again.

.

.

I wanted to tell you that something unusual happened. I left the 12V battery disconnected and connected it again yesterday. At first, it worked for a few minutes and then stopped, so the 12v reset didn't work. I decided to measure the sensor, and although I don't have an oscilloscope, I measured one side, rotated, measured again and repeated the process. The voltage on each channel was at 5v and then dropped when turning the shaft; it seemed that the sensor was fine.

Then I thought about measuring it in motion, since it is a square signal, it should show approximately half the voltage on each channel while it is running, and indeed it was around 2.5V on each channel. Before turning it on for the test in motion, I decided to push the low voltage connector of the inverter (where the signal from this sensor comes in) to make sure there was no false contact. The second time I turned it on after moving the connector, it worked for two hours. I turned it off, turned it back on, and it worked fine for another 10 minutes; I turned it off, turned it back on, and it worked for 20 minutes.

I tried it this morning, and it failed after 3 minutes. I pushed the connector back in, and it's been working for about 45 minutes now.

I think it might be a problem with one of these two connectors or the wire that goes to them. I had previously checked the internal connector, and although the solder joints looked bad, and I got a bad continuity reading at first, when I tried to confirm the bad continuity, it no longer showed continuity faults, so I ruled out that it was bad. Also, since the connector is covered in a transparent soft gel, re-soldering it is not easy, so I assumed it was good.

Long story short, sensor voltages are ok, i suspect the connector on the image is bad. Even on this image that is for an item on sale the welds looks extremly bad like mine.

@asavage After your car failed, turn it off and then could you please try to unplug then plug again(or just push it) the low voltage connector the one on that is near of the high voltage cables on the DI. then turn it on and test it again.

Last edited:

Thanks for the quick reply, yes it could be but there is a screw that make an electrical connection between the connector and the inverter also previously in one of the other attemps to fix this issue I have cleaned and bend those metal strips to improve the contact with the chassis. I'm very sure that the issue is related to those very bad welds.There is a small but non-zero probability of (intermittent) poor contact in these connections (1 case).View attachment 1154

I have tested again 3 times in a row without touching the low voltage connector and all failed within 1 minute. Then i pressed the connector and it worked fine for 11 minutes until i turned it off(don't have more time to test).

I'll be removing the motor and resolder this connector this night i hope to test it again tomorrow, and share an update.

Hi,

I tried to test it yesterday, but I think the result was worse, lol. My solders were duller than the original ones and now it works less frequently than before. What I did notice is that it seems to be a bad contact problem, since when measuring the voltage without the sensor I get 5.4V, but when connecting it it drops to 4.7V. Also, I suspect that there might be also a ground chassis connection issue, because when measuring from ground it detects voltage. If it were completely isolated, there should be no voltage, but it seems that the ground connection is not good, since there is a voltage difference between 12v ground and 5v ground.

I also tried to make a bridge between both grounds, but the results were not conclusive: sometimes it works and sometimes it doesn't.

Could someone please test the voltage between encp , encg and chassis ground? pinout reference on this post.

I tried to test it yesterday, but I think the result was worse, lol. My solders were duller than the original ones and now it works less frequently than before. What I did notice is that it seems to be a bad contact problem, since when measuring the voltage without the sensor I get 5.4V, but when connecting it it drops to 4.7V. Also, I suspect that there might be also a ground chassis connection issue, because when measuring from ground it detects voltage. If it were completely isolated, there should be no voltage, but it seems that the ground connection is not good, since there is a voltage difference between 12v ground and 5v ground.

I also tried to make a bridge between both grounds, but the results were not conclusive: sometimes it works and sometimes it doesn't.

Could someone please test the voltage between encp , encg and chassis ground? pinout reference on this post.

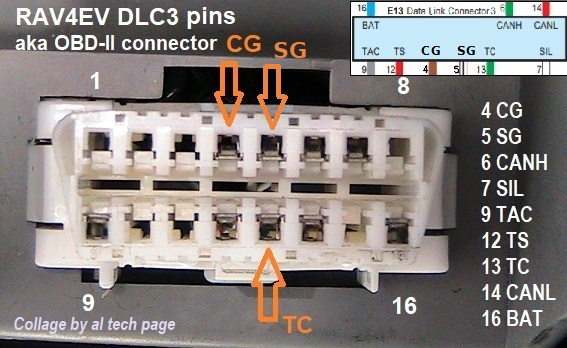

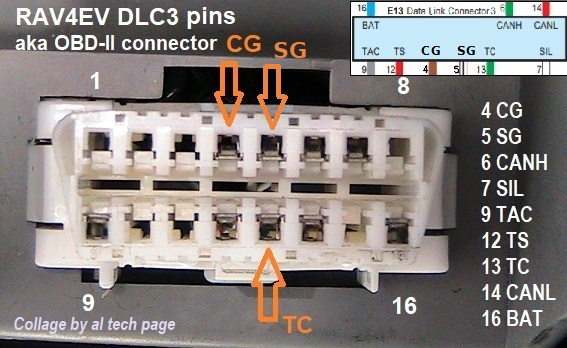

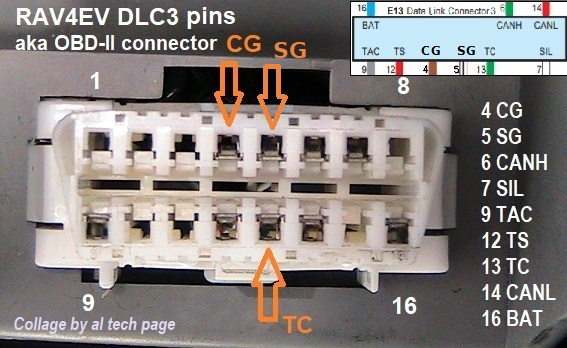

Note: Toyota uses two related but separately implemented ground (negative) circuits.

CG mean Chassis Ground and SG - Signal Ground.

https://alflash.com.ua/2019/to_rav4ev/obd2_0290.jpg

Check the voltage between these two contacts in the diagnostic connector, which Toyota calls DLC3

Sometimes there are such troubles

https://alflash.com.ua/2019/to_rav4ev/bad_sg.jpg

https://alflash.com.ua/2019/to_rav4ev/bad_con.jpg

CG mean Chassis Ground and SG - Signal Ground.

https://alflash.com.ua/2019/to_rav4ev/obd2_0290.jpg

Check the voltage between these two contacts in the diagnostic connector, which Toyota calls DLC3

Sometimes there are such troubles

https://alflash.com.ua/2019/to_rav4ev/bad_sg.jpg

https://alflash.com.ua/2019/to_rav4ev/bad_con.jpg

Last edited:

Note: Toyota uses two related but separately implemented ground (negative) circuits.

CG mean Chassis Ground and SG - Signal Ground.

https://alflash.com.ua/2019/to_rav4ev/obd2_0290.jpg

Check the voltage between these two contacts in the diagnostic connector, which Toyota calls DLC3

Sometimes there are such troubles

https://alflash.com.ua/2019/to_rav4ev/bad_sg.jpg

https://alflash.com.ua/2019/to_rav4ev/bad_con.jpg

I checked it and it seems to be fine, everything is at 0 ohm. Just between ENCG ground and Chassis ground has a high value, not sure if this is normal? I also tested the wiring harness between the 23 pin molex connector and the encoder with an external 5V power supply and the voltage is very constant, not like with the 5V supplied by the inverter, so the wiring harness is fine.

I suspect that either the inverter board is not supplying 5V consistently or there is a faulty connection inside the inverter, between the main board and the outside inverter connector.

What is the numerical value of the voltage difference between them?... Just between ENCG ground and Chassis ground has a high value, not sure if this is normal?

Voltage between ENSP pin (#9) of D14 connector and Chassis ground?I also tested the wiring harness between the 23 pin molex connector and the encoder with an external 5V power supply and the voltage is very constant, not like with the 5V supplied by the inverter, so the wiring harness is fine.

I suspect that either the inverter board is not supplying 5V consistently or there is a faulty connection inside the inverter, between the main board and the outside inverter connector.

Voltage between ENSP pin (#4) of D1 connector and Chassis ground?

https://alflash.com.ua/2019/to_rav4ev/w_sp_sens.png

It would be useful to track and compare all these voltages with and without a fault.

It is a pity that the recommended voltage check (at Ready) between CG and SG was not done in both states of the car (good vs. faulty).

Notes. 1.The resistance measurement is done at very low currents of the measuring bridge of DVOM. And, as I hope, when 12V battery was disconnected.

But this is a test for a break, but not a test for the quality of the connection.

The recommended Voltage Check in this situation is more informative/more relevant for this vehicle. Because in this situation, noticeably large currents flow through the ground wires.

2.SG white with black stripe wires have several connections to the vehicle body.

Last edited:

Hi,

Thanks for the follow up. These are the values:

CG to SG is 0V 0 ohms

ENCG to CG is 20 ohms without 12V battery and in operation there is a voltage of 1.3V

ENCP to ENCG 4.3V with the sensor connected 5.4 without the sensor.

ENCP to CG 5.4V with and without the sensor

When connecting the external 5V power supply to ENCP and ENCG on the molex 23 connector (harness wiring) the voltage did not drop, so I think it is related to some bad connection on the parts that are in this picture.

I will test the continuity from pins 9, 10, 16 and 17 of the D14 connector to the board on pins 5-8 (parts in the picture). If I don't find anything, I will try to feed the inside of D14 with 5V and connect the sensor and check where the voltage drops. If everything is ok, I will try to power the main board with 12V via D14 and check if the board is able to maintain the 5V voltage. I hope I don't burn anything or brick the board, as it won't find any IGBT boards.

Thanks for the follow up. These are the values:

CG to SG is 0V 0 ohms

ENCG to CG is 20 ohms without 12V battery and in operation there is a voltage of 1.3V

ENCP to ENCG 4.3V with the sensor connected 5.4 without the sensor.

ENCP to CG 5.4V with and without the sensor

When connecting the external 5V power supply to ENCP and ENCG on the molex 23 connector (harness wiring) the voltage did not drop, so I think it is related to some bad connection on the parts that are in this picture.

I will test the continuity from pins 9, 10, 16 and 17 of the D14 connector to the board on pins 5-8 (parts in the picture). If I don't find anything, I will try to feed the inside of D14 with 5V and connect the sensor and check where the voltage drops. If everything is ok, I will try to power the main board with 12V via D14 and check if the board is able to maintain the 5V voltage. I hope I don't burn anything or brick the board, as it won't find any IGBT boards.

Attachments

Last edited:

Sir, please, let me know at Ready mode voltage between ENCG and Chassis ground.

And between CG and SG pins of DLC3?

And between CG and SG pins of DLC3?

... Just between ENCG ground and Chassis ground has a high value, not sure if this is normal?

What is the numerical value of the voltage difference between them?

Ready mode voltage between ENCG and Chassis ground is 1.3VSir, please, let me know at Ready mode voltage between ENCG and Chassis ground.

And between CG and SG pins of DLC3?

between CG and SG pins of DLC3 is 0V

Similar threads

- Replies

- 51

- Views

- 5K

Latest posts

-

-

-

-

READY ON not available due to charging cable connection

- Latest: patricknicolello095@gmail

-

-