Rakesh Suresh

Well-known member

- Joined

- Sep 5, 2024

- Messages

- 110

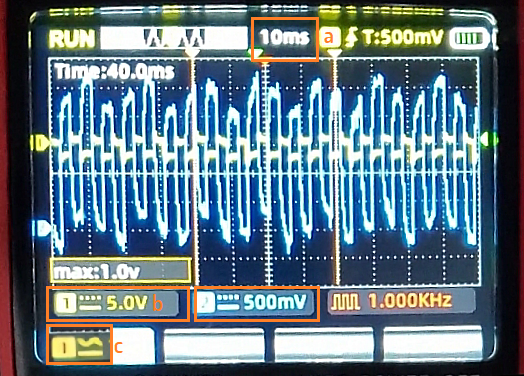

I tested with 100Hz, with ne555

At highest temp: https://1drv.ms/v/s!AoMSicNQxi7y5l0rurHTAl7w-iqS

At lowest temp: https://1drv.ms/v/s!AoMSicNQxi7y5l6Xvp-w6h47uPL4

No change in aluminum temp even after 5 mins of it running.

At highest temp: https://1drv.ms/v/s!AoMSicNQxi7y5l0rurHTAl7w-iqS

At lowest temp: https://1drv.ms/v/s!AoMSicNQxi7y5l6Xvp-w6h47uPL4

No change in aluminum temp even after 5 mins of it running.