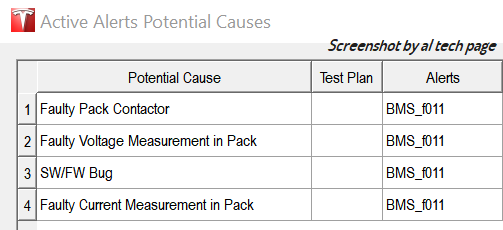

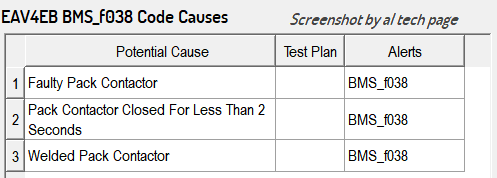

My 2013 RAV4EV recently died on the freeway. I hit the accelerator to change lanes, the was a clun,k and I lost all power. I got safely to the side of the road, tried waiting and restarting a few times, then called for a tow. Wife and I traded cars, and she waited for the truck. When the to came, she was able to get the car moving enough to help get it loaded. Maybe between us we did the 'on/off 5 times magic spell'. Anyway, car was towed to Magnussen's in Palo Alto. Their diagnosis is that we need a new battery pack. Many codes in their diag report (Toyota P312F-448, BMS_f001, DI_f037, BMS_f011, BMS_f038), but the last (BMS_f038) seems most relevant.

Car is driveable now, but the Check EV System warning is still there. If I have a contactor problem, is it likely to cause me to lose power again under normal driving conditions, or only if if I hit the 'gas' for hard acceleration? I can reign in me need for acceleration if that will reliably get me 30 miles for my daily commute.

This forum was very helpful a few years back, when I replaced the OBC fuses to breathe more life into my car.

Looking for another breath of fresh electrical driving,

Jeff

Car is driveable now, but the Check EV System warning is still there. If I have a contactor problem, is it likely to cause me to lose power again under normal driving conditions, or only if if I hit the 'gas' for hard acceleration? I can reign in me need for acceleration if that will reliably get me 30 miles for my daily commute.

This forum was very helpful a few years back, when I replaced the OBC fuses to breathe more life into my car.

Looking for another breath of fresh electrical driving,

Jeff