You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My own experiences fixing a RAV4 EV not charging/fuse blown issue

- Thread starter dfergenson

- Start date

Help Support Toyota Rav4 EV Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

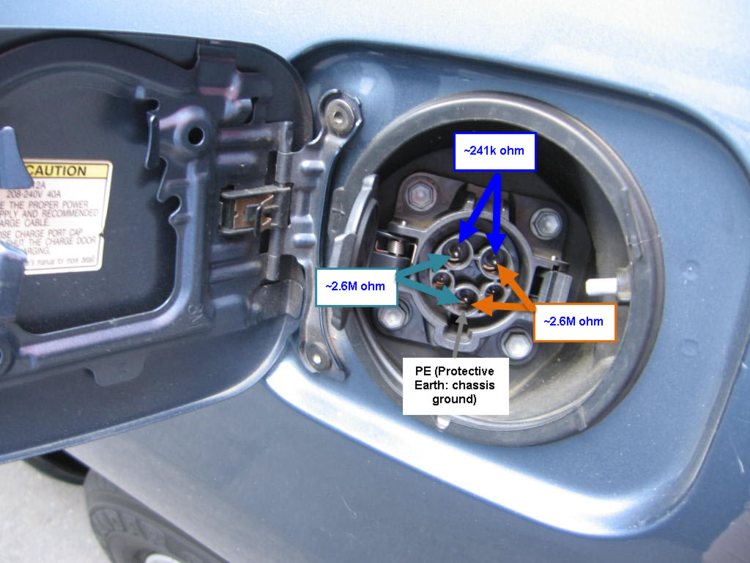

Those measurement values were taken using a Fluke 79 S2, which is an older standard DMM. As I'm measuring for an open fuse, it should suffice.

I also own a Fluke 23 for low-end tasks, a Fluke 289 for datalogging, and a Fluke 1507 Insulation Tester, which while not being a megohmmeter, it will function similar to one in many circumstances. I picked up the latter for use with coolant-soaked LDU stators I would never subject an unknown circuit to the high voltages of a megohmmeter or insulation tester, which would likely destroy something; both devices generate far too high voltage to apply to most circuits I work with.

I would never subject an unknown circuit to the high voltages of a megohmmeter or insulation tester, which would likely destroy something; both devices generate far too high voltage to apply to most circuits I work with.

---

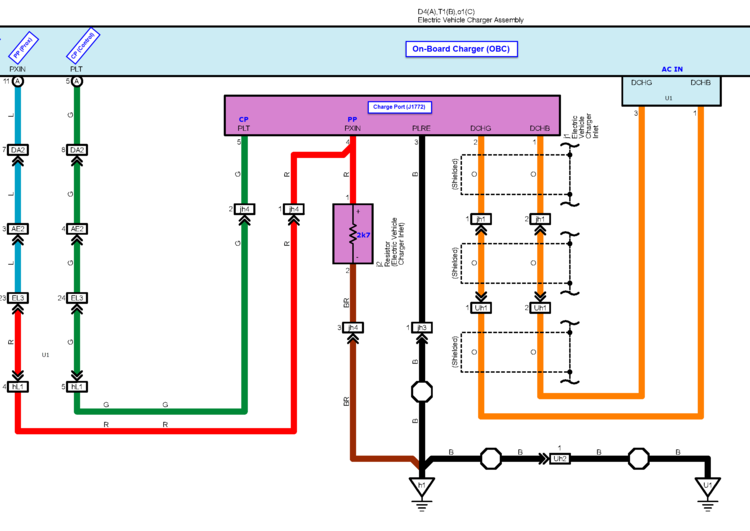

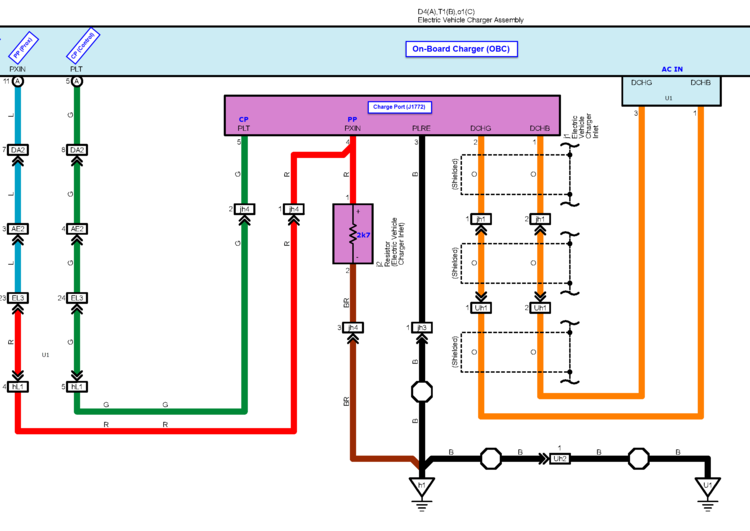

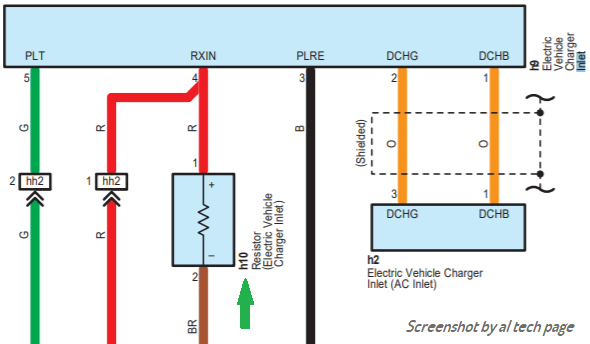

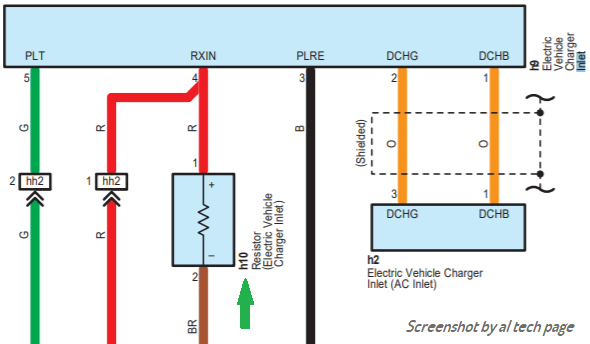

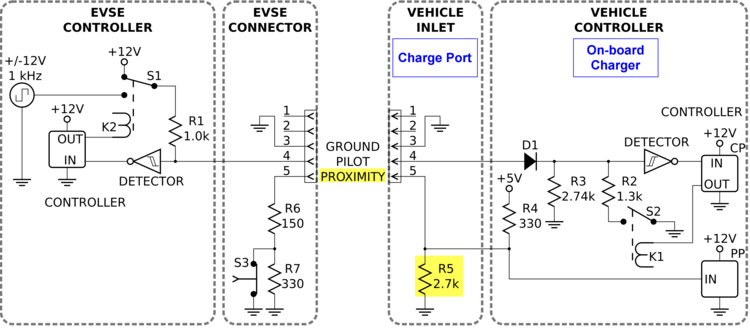

The PP resistor furnished on the RAV4 EV is the SAE_J1772 specified 2k7 (link to Wiki) for the vehicle-side, and which is identified as "j1" on the Toyota diagram:

.

.

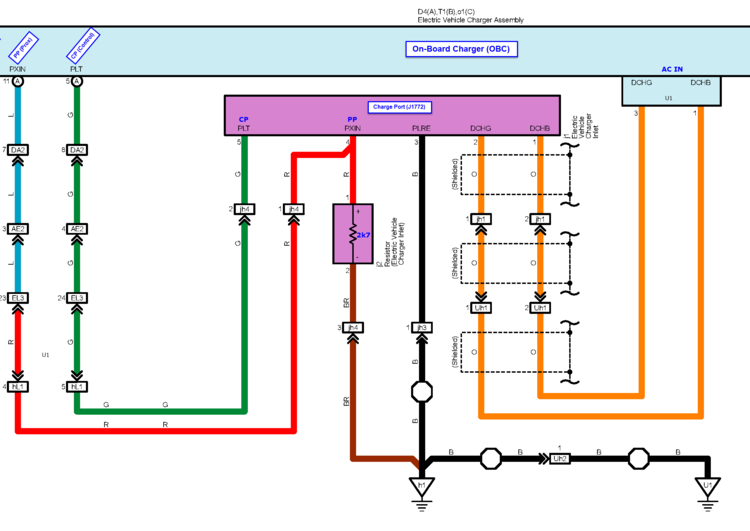

[That's an abbreviated version of the drivetrain wiring; for info on the full version, see this thread]

I have a breakout harness installed to the OBC's Logic Connector (identified as "X042" when installed on the Model S, and "D4" by Toyota), so it was easy to disconnect the PP line and check that resistor both from the Toyota harness and then again at the Charge Port to verify that it's 2k7, even with the OBC out of circuit. I assume that it's physically located at the rear of the charge port.

Breakout harness:

Measurement of PP:

I also own a Fluke 23 for low-end tasks, a Fluke 289 for datalogging, and a Fluke 1507 Insulation Tester, which while not being a megohmmeter, it will function similar to one in many circumstances. I picked up the latter for use with coolant-soaked LDU stators

---

The PP resistor furnished on the RAV4 EV is the SAE_J1772 specified 2k7 (link to Wiki) for the vehicle-side, and which is identified as "j1" on the Toyota diagram:

.

.[That's an abbreviated version of the drivetrain wiring; for info on the full version, see this thread]

I have a breakout harness installed to the OBC's Logic Connector (identified as "X042" when installed on the Model S, and "D4" by Toyota), so it was easy to disconnect the PP line and check that resistor both from the Toyota harness and then again at the Charge Port to verify that it's 2k7, even with the OBC out of circuit. I assume that it's physically located at the rear of the charge port.

Breakout harness:

Measurement of PP:

1. You showed the results of measuring the resistance between the contacts, which are supplied with a high alternating voltage of 120 or 220 volts by the ground contact, which is connected to the body of the car.asavage said:alflash said:

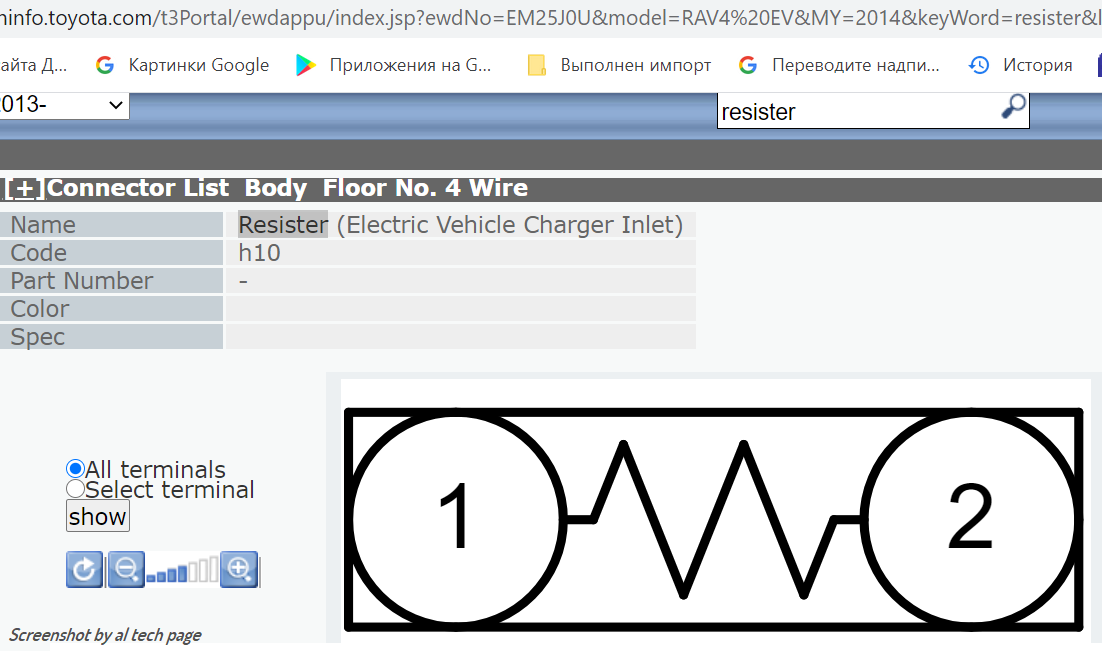

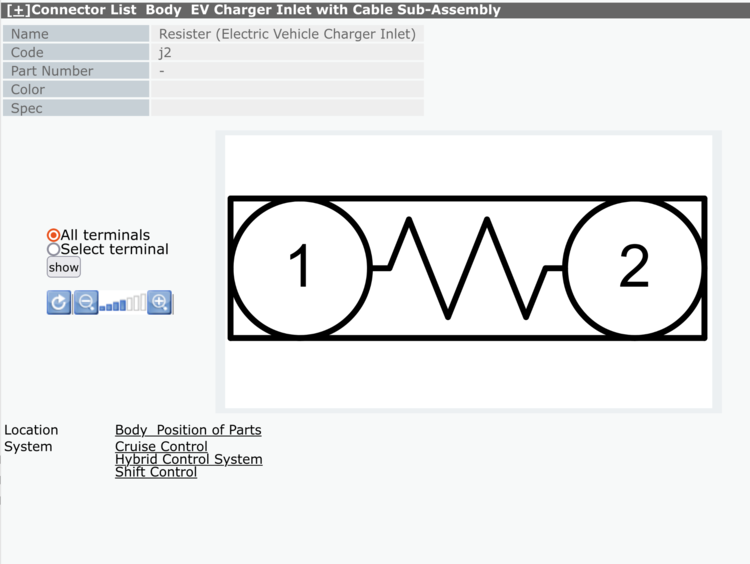

Connector j2 is the one referenced in the 2014 RAV4 EV diagram that I have:

...

My manual (2014 RAV4 EV EM25J0U) does not have an "h10" connector listed at all . . . interesting

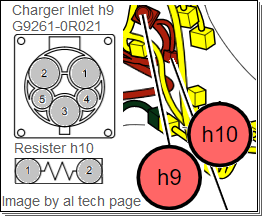

According to Toyota information (https://techinfo.toyota.com/techInfoPortal/) this resister* has code/number/name h10

2. Repeated practical measurements of the resistance of this resistor on a PAB4EV auto showed that

a) it is not located in the charging cable, but is located next to the charging port as a separate device;

b) its actual resistance is not what is indicated in your description, but is 2.4 kOhm

c) the location of the h10 resistor

If needed, I can make a live video (as of May 2023 when connected directly to TIS) of the wiring screen of the connection to the charging port and the charger and naming this resistor (h10) .

Note. The primary source of information about North American Toyotas is

https://techinfo.toyota.com/techInfoPortal/appmanager/

alflash said:1. You showed the results of measuring the resistance between the contacts, which are supplied with a high alternating voltage of 120 or 220 volts by the ground contact, which is connected to the body of the car.

According to Toyota information (https://techinfo.toyota.com/techInfoPortal/) this resister* has code/number/name h10

A megohmmeter (and insulation tester) can provide 1kv during testing, so I would never use it on the AC input of a J-1772, which probably is rated for no more than 600VAC/850VDC.

The PP resistor (sometimes misspelled by Toyota in their connector descriptions as resister, which in English is a person who resists, not an electrical component [shrug]) is not in the AC circuit, except for sharing Ground.

As a test for an open fuse, measuring between the L1/N or L1/L2 contacts to PE/Chassis Ground should be an effective way to quickly determine if a fuse is open. Upthread, you asked me if I had measured the PP resistance . . . why is the PP 2k7 resistor being discussed? AFAICT, measuring the PP circuit on the vehicle would not aid in diagnosing a failed OBC.

alflash said:2. Repeated practical measurements of the resistance of this resistor on a PAB4EV auto showed that

a) it is not located in the charging cable, but is located next to the charging port as a separate device;

Yes, that's what I said I assumed above, "I assume that it's physically located at the rear of the charge port." I don't need to know where it is, because I don't plan to ever have to touch it. It's not a fragile nor failure-prone component: they don't break.

alflash said:b) its actual resistance is not what is indicated in your description, but is 2.4 kOhm

You cannot make a measurement of the PP resistor at the charge port and obtain the correct 2k7 reading unless you disconnect the OBC from the circuit, as OBC input D4/11 does not have a high input impedance, and it is connected to the PP resistor; see the red wire in diagram below:

The SAE J-1772 specification is 2k7 ohms, and that's what repeated practical measurements of the resistor on my RAV4 EV show, with the OBC out of circuit.

From the Wikipedia article on J-1772:

With the OBC disconnected at "D4/11" ("X042" in Tesla Model S parlance) via the breakout harness shown in my previous post:

With the OBC connected:

The OBC interferes with the resistance measurement; My DMM displays "OL" and your instrument shows "2.4k". This is not unexpected, nor is the discrepancy between different instruments unusual: my Fluke 79 S2 auto-ranges and your Uni-T does not. Additionally, even if both our instruments were auto-ranging, ohmmeters use different criteria to change ranges. And our two OBCs may have different input impedance depending upon a number of factors, including how recently one has been in use.

alflash said:

c) the location of the h10 resistor

If needed, I can make a live video (as of May 2023 when connected directly to TIS) of the wiring screen of the connection to the charging port and the charger and naming this resistor (h10) .

Note. The primary source of information about North American Toyotas is

https://techinfo.toyota.com/techInfoPortal/appmanager/

How can you explain why your documentation and mine differ? We can only guess . . .

To me, this is an academic discussion, as my vehicle has no PP illness. My screenshots are not live, but captured in late Mar2023. A video of you walking through a Toyota (Snap-On) TechInfo portal will not clear up the discrepancy: we both used the same source and have different info. This is the state of the modern world -- documentation changes and is frequently incorrect -- and I no longer bother about it.

---

Vlad, I respect your knowledge and willingness to contribute here. However -- and perhaps this reflects the barrier of language translation -- I have often felt our conversations to be be . . . adversarial? I love to be corrected when I post a mistake, it helps everyone to correct misinformation, and I do not make 100% correct assumptions, nor is my writing free of simple typographical errors.

Sometimes when you post in response to something I've written, your reply has a "gotcha" tone which is dispiriting, and discourages me from participating. Please be aware of your audience.

1. The megohmmeters I know have a choice of 100 or 500 or 1000 volt test voltage

https://youtu.be/CC4xkCmFXlg

Some models (old design) do not produce more than 400 (336V) volts at all

https://youtu.be/MWxi0gSCadQ

2. I mentioned PP Resister as an example of another possible cause of a charging malfunction (not only charger fuse).

3. I use Toyota term Resister which is used in the repair manual. It's not my business to teach Toyota English.

4. When that Resister was faulty, the resistance test between that pin and the GND was OL.

5. There

are many reasons for the charging malfunction and I believe it is wrong to make a diagnosis only on the basis of my assumptions and / or statistics.

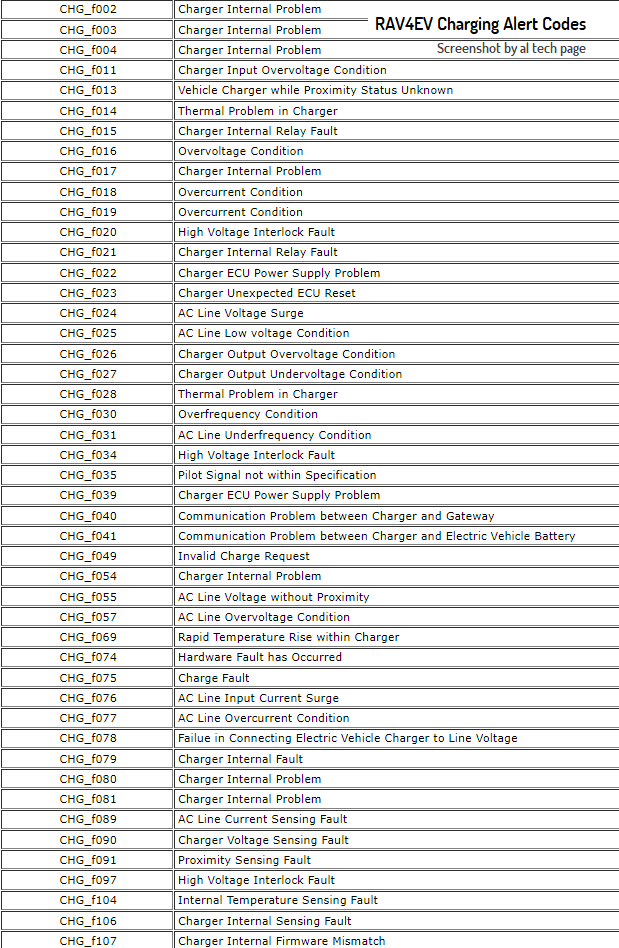

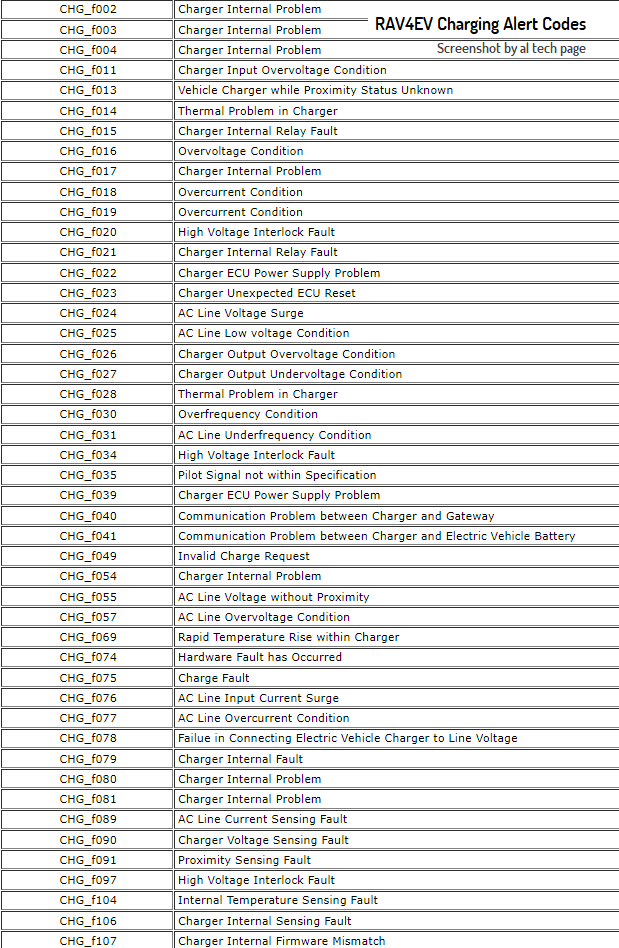

Note. Only one code corresponds to a malfunction of the internal fuses

Please accept my apologies if I violate the rules of this forum and my desire to give justifications / arguments for my versions / comments and the habit of using first-hand information (from the manufacturer) seemed offensive to someone.

All the best and best wishes.

https://youtu.be/CC4xkCmFXlg

Some models (old design) do not produce more than 400 (336V) volts at all

https://youtu.be/MWxi0gSCadQ

2. I mentioned PP Resister as an example of another possible cause of a charging malfunction (not only charger fuse).

3. I use Toyota term Resister which is used in the repair manual. It's not my business to teach Toyota English.

4. When that Resister was faulty, the resistance test between that pin and the GND was OL.

5. There

are many reasons for the charging malfunction and I believe it is wrong to make a diagnosis only on the basis of my assumptions and / or statistics.

Note. Only one code corresponds to a malfunction of the internal fuses

Please accept my apologies if I violate the rules of this forum and my desire to give justifications / arguments for my versions / comments and the habit of using first-hand information (from the manufacturer) seemed offensive to someone.

All the best and best wishes.

$87.78

$99.54

Genuine Toyota 2006-2012 Rav4 Dark Charcoal Carpet Floor Mats Set PT208-42051-11

parts.elmhursttoyota com

$16.06

$16.91

MICTUNING Upgraded Dual USB Port 6.4A QC3.0 Quick Charger with Blue LED Digital Voltmeter Replacement for Toyota, Compatible with Cellphone iPad PDA Laptop GPS (Surface Size 1.6 x 0.9 inches)

Nado Stuff (Authorized Dealer)

Thanks for all of that guidance, got me a step closer to tackling it. However, my resistance numbers at the charge port look normal, so may not be in the "lucky" 80% with just a fuse issue.

asavage said:Other than dealing with the arcane and fussy HVJB connections on the passenger side of the OBC, and possibly having to purchase a fairly inexpensive tool or two that you may not have already -- Torx bits, remote hose clamp tool, etc. -- I found my own experience with replacing the OBC fuses to be straightforward and less difficult than, say, replacing a camshaft timing belt on some ICE's I've owned. Then again, this is sort of in my wheelhouse and I have more experience than some (and less than others). See the end of the thread that alflash linked above.

If the problem is a failed OBC fuse, and if you don't completely drain the blue coolant as dfergenson did, then you don't have to have the proprietary Tesla Powertrain Diagnostics software, and you don't have to run the "coolant air purge" cycle. I opened only the coolant connections needed to extract the OBC from the vehicle, and topped up the blue reservoir a couple of times after reassembly, during the first good charge cycle, with the pump running as usual, and didn't need to run the coolant air purge cycle. I didn't elevate the vehicle, I didn't get under it, and I didn't remove any under-body panels. I did rinse off everything of spilled coolant several times using a garden hose, using my (electric) leef blower to move the excess rinse water away from the work area -- and, my current work area situation allowed me to use a hot-water-rated garden hose connected to my water heater's drain valve, as rinse water, since my work area and the water heater are 10' from each other.

But, if you've got an issue other than a typical failed fuse, then the TPD program is very helpful -- and difficult/expensive to obtain. That's where alflash's services can be helpful.

You may be able to perform a quick test with an ohmmeter at the charge port to determine if an OBC fuse has failed.

Still and all, replacing these fuses (and replacing them both is recommended; at least two people have reported that the other fuse has failed in ~2 years, if it wasn't replaced at the same time as the first) is not "easy". As dfergenson mentions in the first post, in the Model S it's a snap to get to and replace these fuses because the OBC is located under the rear seat, but in the RAV4 -- with the same OBC -- it's much more effort, and the "orphan" nature of this vehicle means that the Tesla bits are not well integrated. Unlike dfergenson, I found the many pics I had taken were very helpful for reassembly and I referred to them often, primarily for harness routing.

jcantor14 said:Thanks for all of that guidance, got me a step closer to tackling it. However, my resistance numbers at the charge port look normal, so may not be in the "lucky" 80% with just a fuse issue.

I agree, and this is one of the cases where using alflash's remote diagnostic service may be a good idea. You'll have to acquire a Mikrotek router and build (or borrow) the interface cable, and you'll probably want a laptop for this, rather than a desktop. Bang-for-buck, for one-off diagnostics, alflash's service can't be beat.

If you're local to the San Diego area, you could try your luck with QC Power, though I don't personally recommend them. They are very familiar with the RAV4 EV but are troublesome to deal with and definitely have been unprofessional to me and others. There are also a few folks around the US who have the TPD software and cable, but this is pretty hit-n-miss, so Vlad is your most reliable help, once you've ruled out the fuses, which you seem to have.

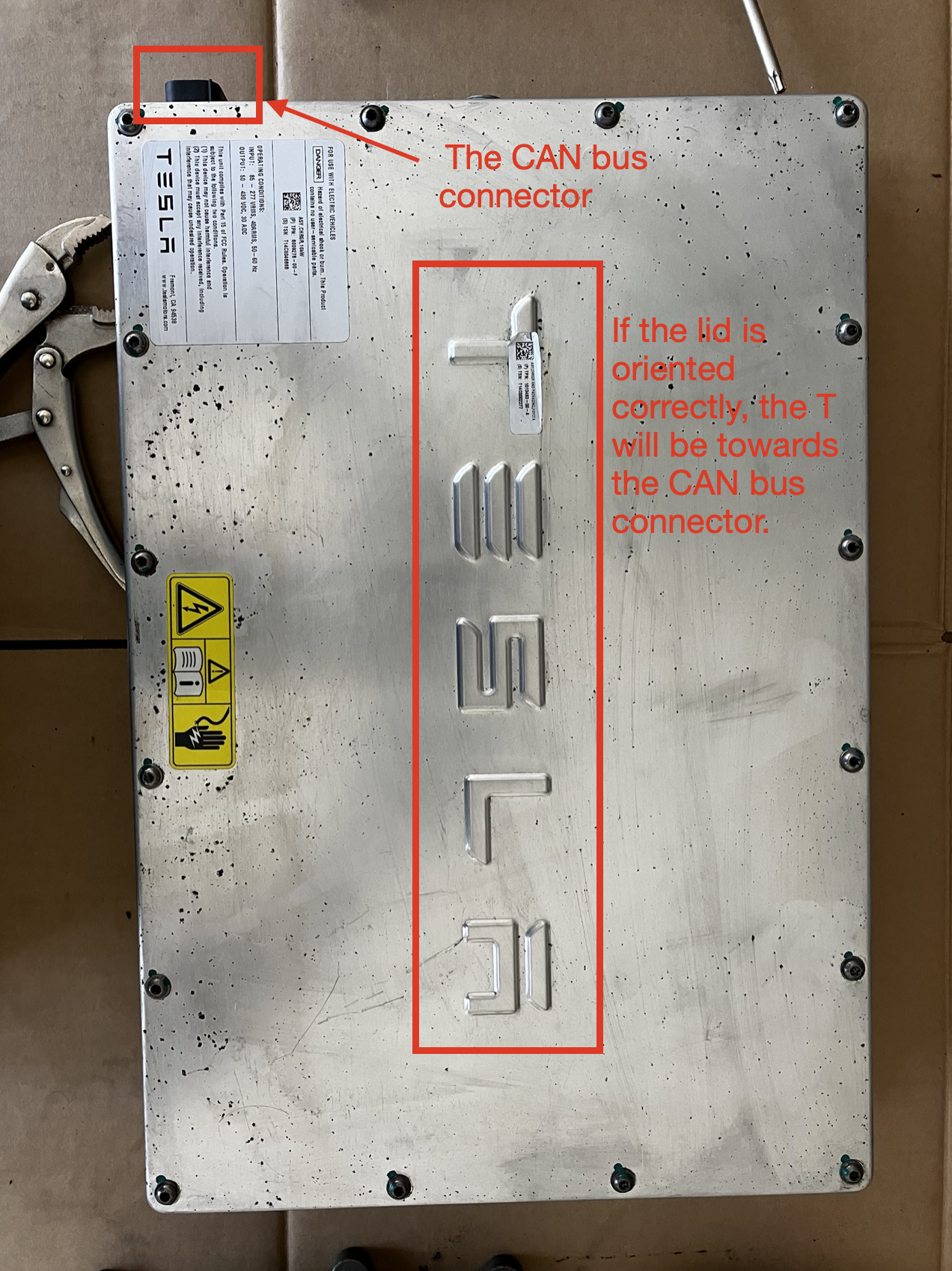

BMS_f071 is a "catch all" DTC that can be caused by many different failures, including HV isolation issues (which includes an LDU coolant-soaked stator), and corroded CAN bus connectors.

Light reading of others who have had that error (in Teslas, of course) suggest both HV isolation issues as well as several other component failures that triggered that code. In the case of the car related to that YT video, did replacement of the charger repair the BMS_f071?

Light reading of others who have had that error (in Teslas, of course) suggest both HV isolation issues as well as several other component failures that triggered that code. In the case of the car related to that YT video, did replacement of the charger repair the BMS_f071?

Excuse me, but i can't keep silentasavage said:BMS_f071 is a "catch all" DTC that can be caused by many different failures, including HV isolation issues (which includes an LDU coolant-soaked stator), and corroded CAN bus connectors.

Light reading of others who have had that error (in Teslas, of course) suggest both HV isolation issues as well as several other component failures that triggered that code. In the case of the car related to that YT video, did replacement of the charger repair the BMS_f071?

If LDU is Motor plus Inverter, then in this case (video) they do NOT have anything to do with the reason for the appearance of this code (BMS_f0171) in the Charging mode.

I have to draw your attention to the fact that charging is done in the IGN OFF mode, in which the Drive Unit "sleeps peacefully" and is NOT involved in any way.

Further, to determine a noticeable deterioration in the Isolation Resistance parameter below the permissible threshold, it is not enough just to switch the car to Ready mode (let me knw if need video demonstration).

Note. In all other modes, no codes/faults were found. The vehicle drives without complaints from the owner.

p.s. I believe that only an inexperienced idiot could come up with such a useless fault code about "nothing"! :mrgreen:

p.s. The Charger of this vehicle is perfectly serviceable!

alflash said:If LDU is Motor plus Inverter, then in this case (video) they do NOT have anything to do with the reason for the appearance of this code (BMS_f0171) in the Charging mode.

I have to draw your attention to the fact that charging is done in the IGN OFF mode, in which the Drive Unit "sleeps peacefully" and is NOT involved in any way.

When the BMS allows the HV contactors to close, the inverter in the LDU (and ALL HV-using devices) is provided with HV: the HV rail becomes hot. The HV contactors can be closed when the car is in Ready mode OR if the car is attempting to charge (ie not Ready mode). In both cases, HV is supplied outside of the HV battery, and the BMS can set a DTC if an isolation fault is detected.

A HV isolation fault can be detected in the LDU (inverter) when the HV contactors supply HV to the LDU. This includes charging mode.

As the TPD screen says (time = 0:34 in your vid), BMS_f071 "is always accompanied by another alert", which is the more granular information. BMS_f071 doesn't indicate much beyond, "BMS has found a problem of some kind". Similar to the generic Toyota DTC P312F that turns on the MIL whenever anything goes wrong with the Tesla parts of the car.

As an example of a possible sequence of events:

- Car is off

- User inserts charging nozzle

- Charg-r detects plug insertion and begins "Charging" startup

- BMS detects request from Charg-r for HV, attempts to close HV contactors, finds fault, etc.

alflash said:Note. In all other modes, no codes/faults were found. The vehicle drives without complaints from the owner.

Ah, well that's vital information I didn't have previously . . . obviously, whatever BMS_f0171 indicates, it doesn't interfere with Ready mode.

alflash said:The charger of this vehicle is perfectly serviceable!</span>

Finally, this statement, at the END of what's come before in this thread, leads me to wonder what your intention is, in this forum. Let me summarize the past few posts:

- I posted a possible "quick test" of a failed OBC fuse (23May2023)

- You asked if I used a megohmmeter*, and asked if I'd checked the PP resistor

- I replied that I own a megohmmeter-equivalent but did not use it, as it wasn't needed AND can be dangerous. I said that I did not test the PP resistor in my car because it was not an issue. I wondered why you asked me about the PP resistor.

- You stated (not opinion: stated as fact) that the PP resistor IS 2k4 (24May)

- I replied that it is 2k7, showed my work, cited an authoritative source, and explained why your 2k4 measurement might deviate.

- You state that a megohmmeter can be set for a safe test voltage on the OBC's input. You did not address the 2k4 vs 2k7 PP resistor**.

- A user posts that they have "normal" readings at the AC inputs on the charge inlet, and presumably have a charging problem (not specified in this thread, so I don't know).

- I recommend the user use a professional's services -- such as yourself -- to further diagnose the unspecified charging issue.

- You post a video about BMS_071 [sic] and working OBC fuses. There is no charging error indicated in the video.

- I respond that in many cases a BMS_f071 DTC does not have anything to do with charging.

- Now you furnish the information that the vehicle in the video is driveable and has a repairable charger.

* = A megohmmeter is not in a DIY's toolset. A DMM is. We know you operate a professional repair facility and have access to these tools, but 99% of people reading this will have access to a DMM at most, and a resistance check of the OBC's fuses, taken at the charge port, is an easy first step. Dragging discussion of a rare test instrument into a DIY discussion, without providing context such as, "If you have good fuses, you may want to use this rare test instrument -- found at a professional repair facility -- to further test/diagnose the HV leads from the charge inlet to the OBC" . . . well, this is unhelpful. Actually, it's actively unhelpful and would discourage someone seeking repair information, because you do not explain when to seek out this tool, you only say, "this is a tool for testing things" and don't say anything else.

** = This is similar to when we had a discussion two years ago when I mentioned a brush in the LDU, and you stated that there is no brush. I then furnished a picture of the Aegis brush. You then modified your earlier post to make it appear as if you knew about it all along, and you used MY picture as evidence. Sheesh.

---

It is obvious that you know a lot about repairing EVs and RAV4s. You can annotate screenshots and make cryptic videos. You own test equipment. You offer a valuable service that is relevant to pretty much everybody here.

What you don't do is add value to our discussions. You don't demonstrate how to test or repair anything. No tips or advice or procedures to test. When you post, it seems like an advertisement, "use my services, I know things," and while advertising has its place, its place is not in the middle of every thread having to do with a potential customer.

Please add value to our community, directly, by offering help that community members are likely to be able to use. Your competence will drive customers to you.

Quick replies to some comments.

I confirmed that I was wrong by making a video that confirms the correctness of your comment about RAV4EV brushes.

The insulation resistance of high-voltage circuits must be measured at their normal voltage. Measuring at a much lower voltage (9 vs. 100÷500 volts DC) can be a source of confusion. Is it really necessary to explain.

For example, the correctness of measuring the insulation resistance between the stator windings and the stator housing (after the G48 hits the motor) with a megohmmeter, and not with a conventional DVOM.

You explained one of the reasons for 2.4 kOhm in my measurements, but my photo shows the result of the actual measurement on a serviceable car and nothing more.

Wasting time proving that the DU is "sleeping" in charging mode, despite the fact that the HV battery voltage comes to the input of the Inverter, I think it's a waste of time on the obvious to me.

A recent video is not an educational one. But those interested can see in it the cause of the charging malfunction, which was one of the subjects of this recent discussion (electrical circuit proximity). Not having accurate information about the algorithm and the content of the checks that are carried out by Tesla before starting charging, I do not undertake to put forward versions, as this will be similar to fortune-telling. Therefore, I show only factual data there.

I consider your version of my unscrupulous motives for participating in this forum to be wrong, but you have the obligatory freedom to make any statements, but not to personal insults. I rarely publish a link to a web page with an offer of free consultations. In harsh words, I do NOT lure clients. But you may consider my motives unscrupulous.

I would be flattered if you would post a list of my false claims in which I misled the people involved in repairing RAV4EV cars.

And the fact that some do not have the necessary equipment (megohmmeter, milliohmmeter, oscilloscope) does not make it superfluous to check with their use.

The fact that not every doctor has a tomograph or ultrasound scanner for personal use does not make them superfluous when searching for the cause of the patient's illness.

With your permission, I will stop the discussion with you, as you go beyond technical issues and move on to discussing my personality and public fabrications/fantasies about the motives of my attempts to help others. Of course, you have the right to criticize my technical errors (in messages and videos) if there is factual evidence of their falsity.

All the best and be healthy, lucky and happy!

With respect to Уou, Sir,

Volodymyr Leshchenko (aka alflash)

p.s. Quotation. "... As an example of a possible sequence of events:

• Car is off

• User inserts charging nozzle

• Charger detects plug insertion and begins "Charging" startup

• BMS detects request from Charg-r for HV, attempts to close HV contactors, finds fault, etc....".

This list/sequence does not exactly match what is shown in the video. Therefore, for example, this item (and not only) "BMS detects request from Charg-r for HV, attempts to close HV contactors, finds fault, etc." is not executed at all and Contactor State does not even try to go to the state "BMS_CTRSET_PRECHARGE" from OPEN state ...

V.L.

I confirmed that I was wrong by making a video that confirms the correctness of your comment about RAV4EV brushes.

The insulation resistance of high-voltage circuits must be measured at their normal voltage. Measuring at a much lower voltage (9 vs. 100÷500 volts DC) can be a source of confusion. Is it really necessary to explain.

For example, the correctness of measuring the insulation resistance between the stator windings and the stator housing (after the G48 hits the motor) with a megohmmeter, and not with a conventional DVOM.

You explained one of the reasons for 2.4 kOhm in my measurements, but my photo shows the result of the actual measurement on a serviceable car and nothing more.

Wasting time proving that the DU is "sleeping" in charging mode, despite the fact that the HV battery voltage comes to the input of the Inverter, I think it's a waste of time on the obvious to me.

A recent video is not an educational one. But those interested can see in it the cause of the charging malfunction, which was one of the subjects of this recent discussion (electrical circuit proximity). Not having accurate information about the algorithm and the content of the checks that are carried out by Tesla before starting charging, I do not undertake to put forward versions, as this will be similar to fortune-telling. Therefore, I show only factual data there.

I consider your version of my unscrupulous motives for participating in this forum to be wrong, but you have the obligatory freedom to make any statements, but not to personal insults. I rarely publish a link to a web page with an offer of free consultations. In harsh words, I do NOT lure clients. But you may consider my motives unscrupulous.

I would be flattered if you would post a list of my false claims in which I misled the people involved in repairing RAV4EV cars.

And the fact that some do not have the necessary equipment (megohmmeter, milliohmmeter, oscilloscope) does not make it superfluous to check with their use.

The fact that not every doctor has a tomograph or ultrasound scanner for personal use does not make them superfluous when searching for the cause of the patient's illness.

With your permission, I will stop the discussion with you, as you go beyond technical issues and move on to discussing my personality and public fabrications/fantasies about the motives of my attempts to help others. Of course, you have the right to criticize my technical errors (in messages and videos) if there is factual evidence of their falsity.

All the best and be healthy, lucky and happy!

With respect to Уou, Sir,

Volodymyr Leshchenko (aka alflash)

p.s. Quotation. "... As an example of a possible sequence of events:

• Car is off

• User inserts charging nozzle

• Charger detects plug insertion and begins "Charging" startup

• BMS detects request from Charg-r for HV, attempts to close HV contactors, finds fault, etc....".

This list/sequence does not exactly match what is shown in the video. Therefore, for example, this item (and not only) "BMS detects request from Charg-r for HV, attempts to close HV contactors, finds fault, etc." is not executed at all and Contactor State does not even try to go to the state "BMS_CTRSET_PRECHARGE" from OPEN state ...

V.L.

Additionally, you have repeatedly edited your old posts to make it appear retroactively that you said something accurate, after I corrected you, as you have done to your post just previous to this one. This changing of history is very annoying; it makes it appear that I responded to something that is no longer present.

Yes, we will not be conversing further, as your motives and presentation are both suspect in my eyes.

Yes, we will not be conversing further, as your motives and presentation are both suspect in my eyes.

I just wanted to post a thank you to OP on this thread for the information shared. The information in these forums allowed me to diagnose the problem with my vehicle and gave me the confidence to be able to replace the fuses on my own.

I live in Phoenix and couldn’t find anyone who would take the job. The Toyota dealership wanted to replace the entire onboard charger for over $6000 but they couldn’t find a replacement part to do the job. I spent about $130 on the fuses, about 15 hours of my time (limited mechanic skills and tools), and another $400 for towing to dealership, codes reset, and two fluid systems flushed (the pink and blue).

I live in Phoenix and couldn’t find anyone who would take the job. The Toyota dealership wanted to replace the entire onboard charger for over $6000 but they couldn’t find a replacement part to do the job. I spent about $130 on the fuses, about 15 hours of my time (limited mechanic skills and tools), and another $400 for towing to dealership, codes reset, and two fluid systems flushed (the pink and blue).

JasonA

Well-known member

Gonna bump this.. I also have the BMS 071 / charger issue probably. Gonna start digging into mine and this is good info to have.

Thanks team..

Thanks team..

AFAIK, only ONE fuse fails at a time -- both legs of the incoming AC are fused -- but best practice is to replace them both.I might hit you up on some of that info once I get the charger out and take a look. Hopefully its the charger fuses... fingers crossed

The HV connections at the passenger side of the OBC are the fussiest, because it's a mirror-on-a-stick job. A lot of connectors. And the OBC itself is over 40 lbs, so on the heavy side.

JasonA

Well-known member

Sounds like a good time!!  NOT!

NOT!

This is starting to remind me of the good'ol Leaf days and hacking, etc. except I wasn't planning on diggin back into this with the Rav...

Ohh fun.. if only the wife didn't love this thing sooo much.... (plus it has a new factory paint job only 3mo old)

Thanks for info bud! I'll prob start pulling stuff off this week.

This is starting to remind me of the good'ol Leaf days and hacking, etc. except I wasn't planning on diggin back into this with the Rav...

Ohh fun.. if only the wife didn't love this thing sooo much.... (plus it has a new factory paint job only 3mo old)

Thanks for info bud! I'll prob start pulling stuff off this week.

Arlin

Well-known member

Any other ideas here? Looks like these are a ways away and VERY pricey. Looking for cost effective fuses that I can get from Digikey or Mouser or Amazon etcRAV4 EV charging issue case study for MyRAV4EV forum:

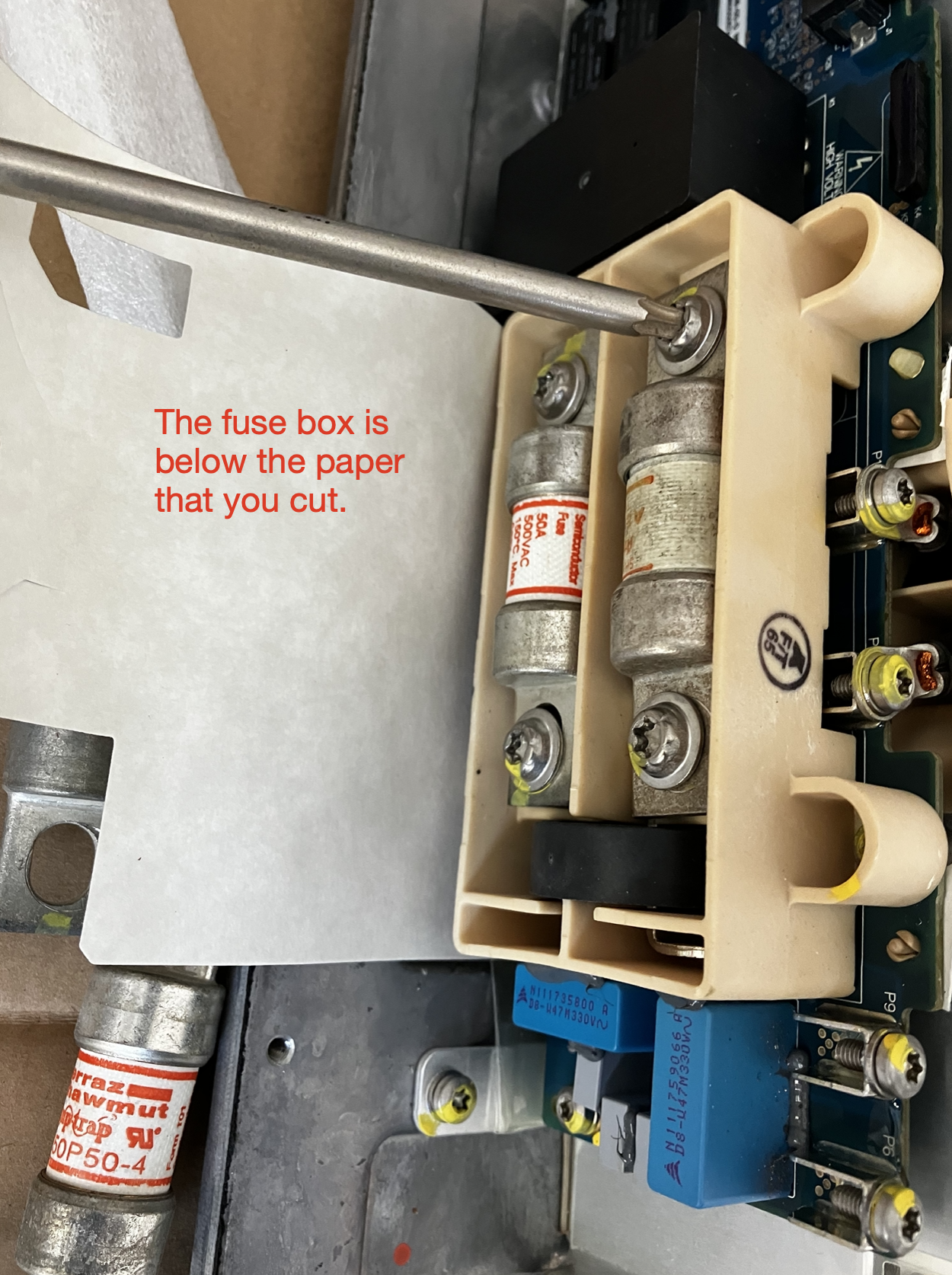

The fuses are Ferraz Shawmut Amptrap fuses, model A50P50-4, Form 101. There are a bunch of equivalents from other fuse manufacturers but be careful when you choose one because there’s something confusing in the specification: Form 101 does not refer to a form factor; it refers to an electrical characteristic. For example, the A50QS50 fuse that is located in the battery junction box (more about this later) is also a Form 101 fuse but it is too large for the onboard charger fuse holder. Also worth noting, Ferraz Shawmut fuses are now being produced by a different company, Mersen. The part numbers are the same. I was able to purchase three of the Ferraz Shawmut fuses for $30 including shipping on eBay but there are a lot of suppliers for these fuses.

-Davio

Rakesh Suresh

Well-known member

- Joined

- Sep 5, 2024

- Messages

- 110

Similar threads

- Replies

- 18

- Views

- 2K

- Replies

- 253

- Views

- 12K