alflash said:

asavage said:

.... I think I'd rather sacrifice the ball bearings.

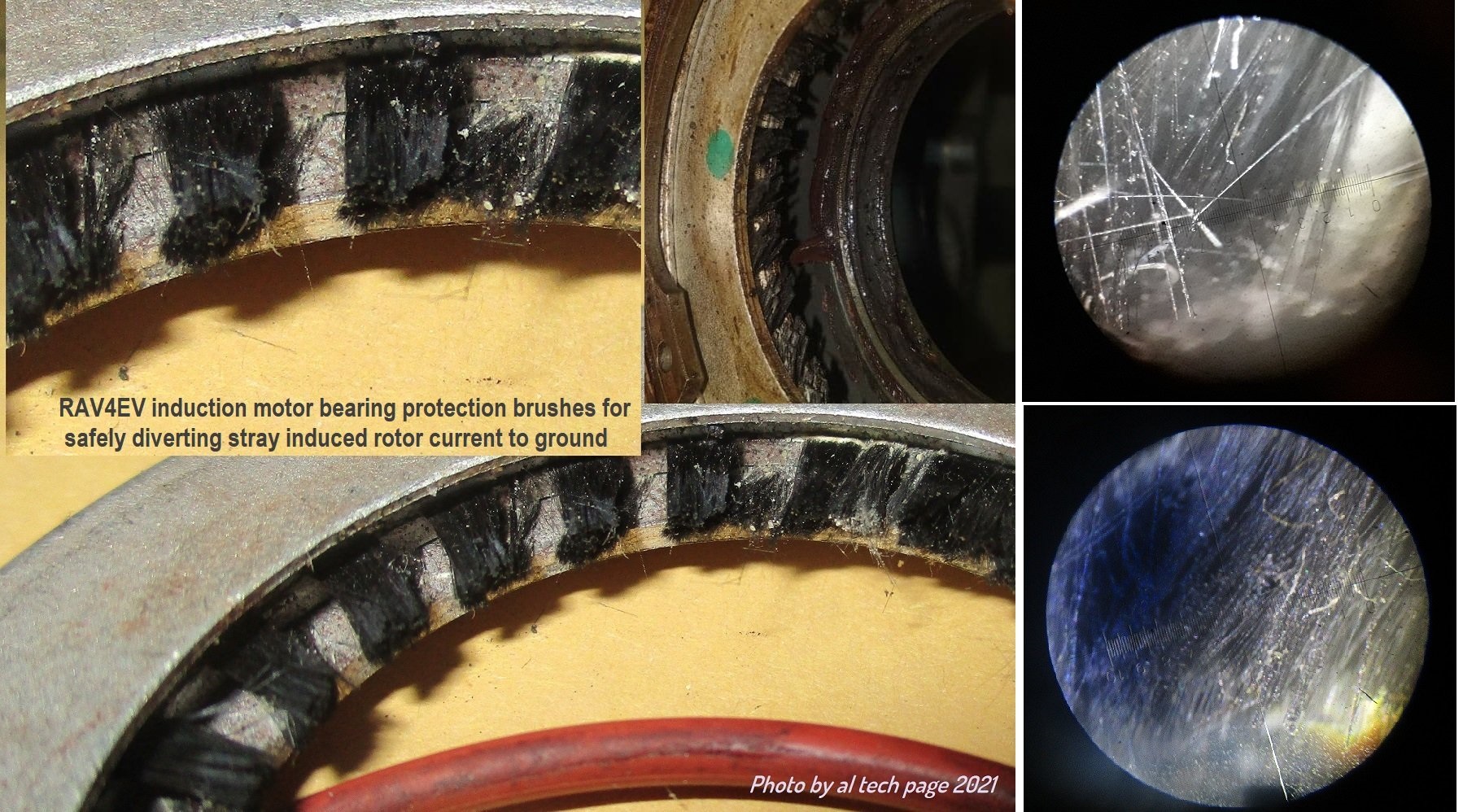

Where are the brushes in this motor?

It took a few months, but there's my reply:

[Sep2022: BTW, not a nice trick, you taking my pictures above, editing them, and inserting them months later into your own post above. That changes the reading of this thread quite a bit.]

james said:

I believe the recommendation is to replace the coolants at 50K miles. I wonder if replacing the coolants sooner would better protect the seals from leaking? Perhaps water content in the coolant is causing the seals to fail.

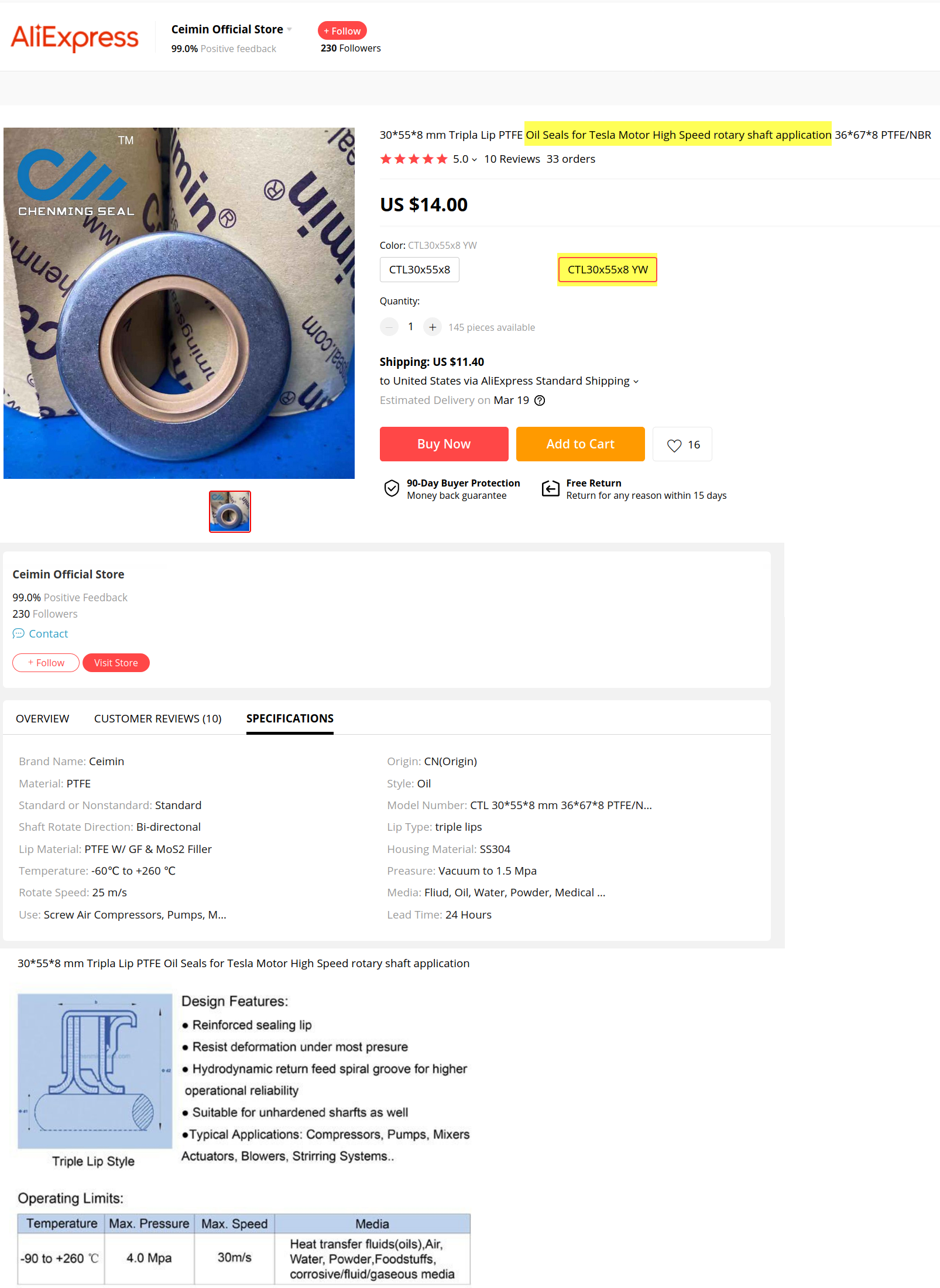

Hazarding a guess, it's the speed of the rotor (the feet-per-minute spec of the seal). But, I am not a seal engineer by a long stretch, so this is only a guess.

Particulates (in particular, yuk yuk) plus that high rate of f/min could lead to unreasonable wear from an durability engineering perspective.

james said:

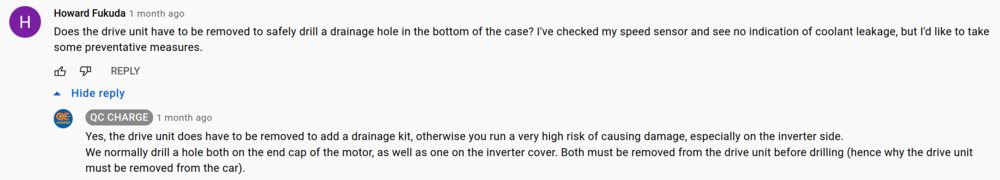

This issue seems to be one of our biggest issue going forward. Would it be possible to modify the speed sensor with a sensor to catch this problem quickly before catastrophic damage?

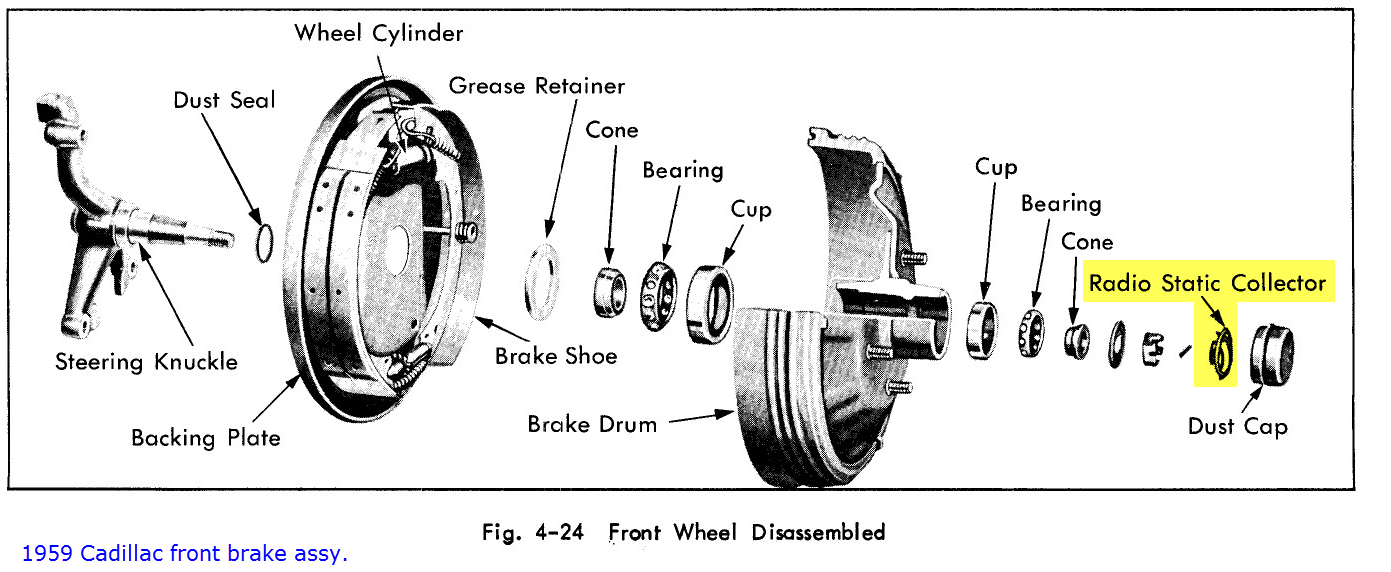

The speed sensor is located at nearly the highest place in the motor that could sense stray moisture, though of course that's where people check because it can be unbolted easily. Removing the speed sensor as a spot check is great, but I'd rather sense moisture at the low end, where gravity can assist, and which would yield an earlier warning. I rather like

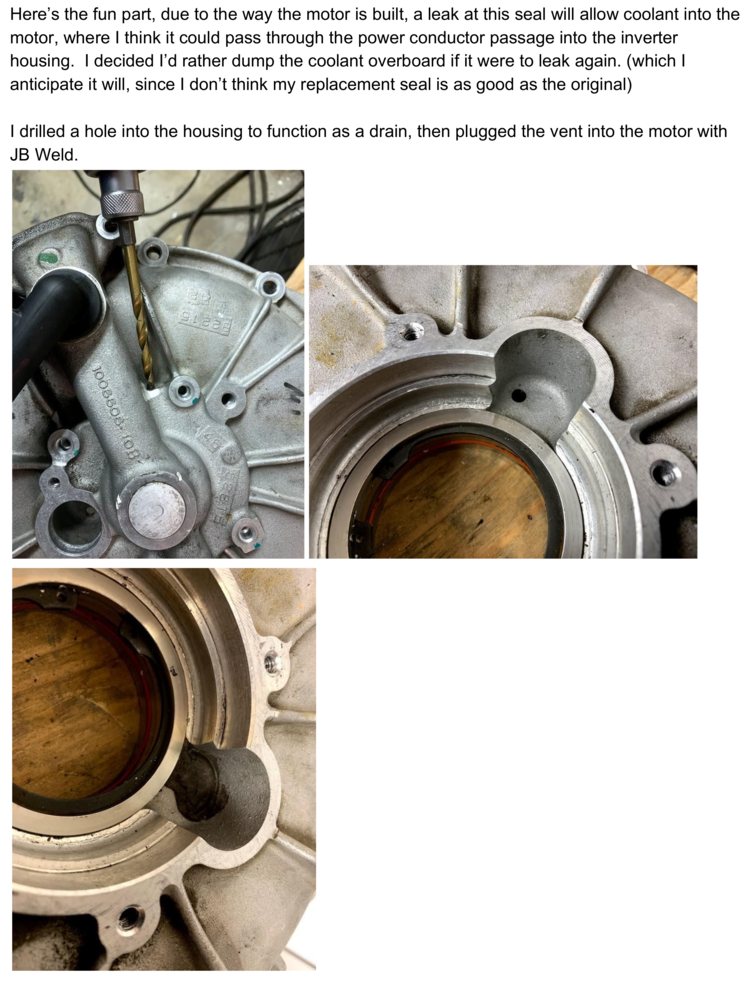

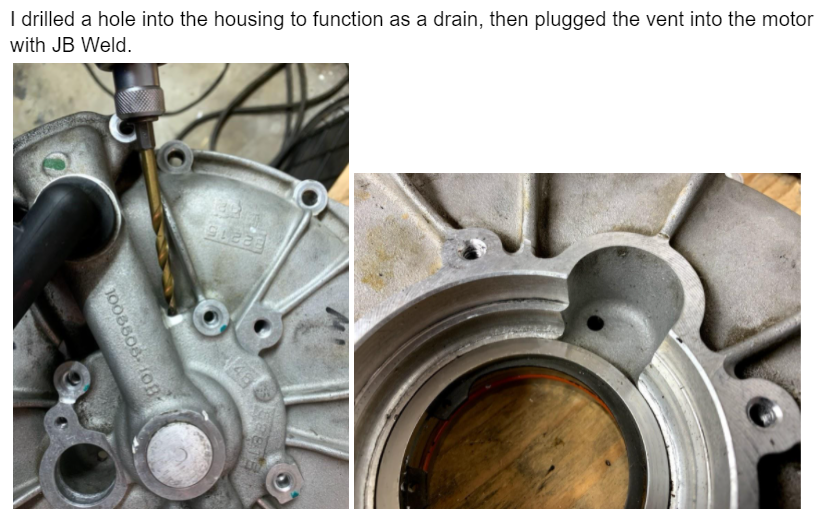

alflash's low location at the bottom of the motor case, just to one side of the internal lateral water passage from the rotor end housing to the inverter.

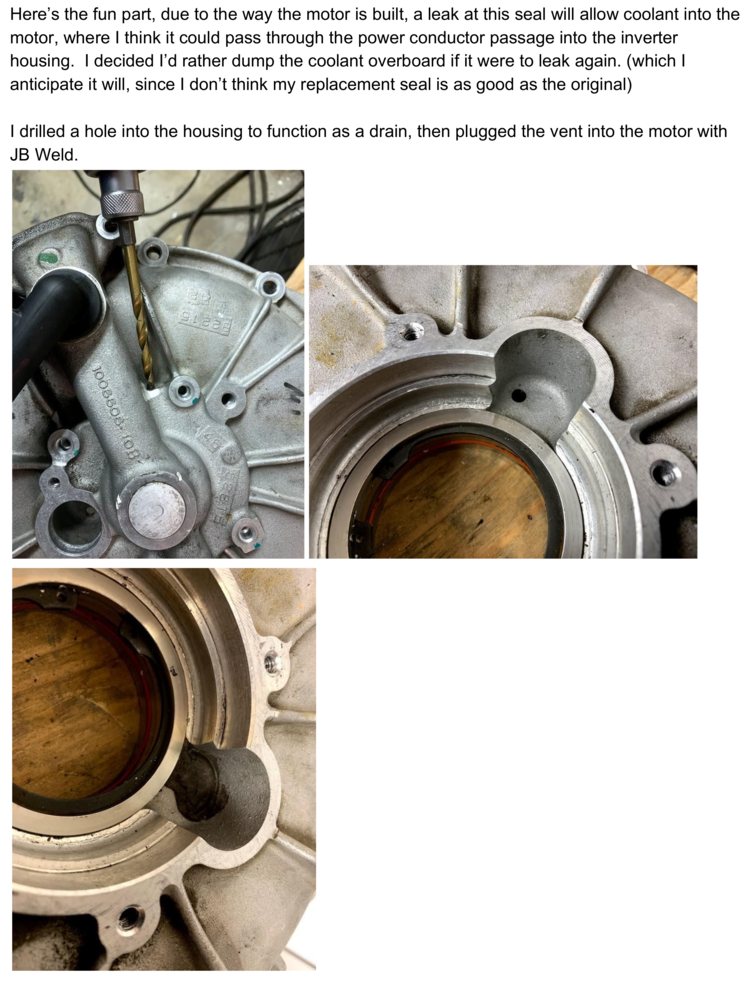

The OP's drain location in the rotor end housing:

That location would likely catch a leak in the seal quickly, but might miss a leak at the inverter end for quite a while. While I've not heard reports of an internal leak in other areas of the old Tesla DUs, there are a few more coolant joints (inverter heat sinks have some) and I'd like to install one sensor that covers everything.

A few months back, I was scouting for the perfect place to drill a ~10mm hole, in which to insert an adapter and tiny drain line (or just a probe adapter), to which I could attach a moisture probe (essentially, a pair of electrodes). Once that mechanical tap is in place, a variety of ways to trigger alarms, bells, whistles, indicators, or automated email alerts every time you open your phone, could be deployed.

Going in blind, I'd want two pieces of information: the location to drill, and the depth. Lacking that, I'd need a donor motor case and the rotor end casting to take measurements myself. Since I have neither, I put my own personal project on back burner status until some other projects around here get sorted. It's on my To-Do list. I suppose if nobody else posts the info, I should go scouting for a junk half-motor. I don't need any of the expensive bits (inverter, gearcase). I've got a couple bookmarked, but again it's too far down my list right now.

james said:

Also, who, other than Tesla, can replace the seals?

According to a

"EV Repair Technician at QC Charge", QC Charge (QC Power on Twitter) in far SoCal does it. I no longer work with Tony/QCP -- I've fired him as an approved vendor after three strikes -- but they are an available resource.

Rich Rebuild's shop,

Electrified Garage have not replied to my multiple emails on this topic, so I assume that they're also not seriously in business. If you don't communicate with your customers, you're not a business. Having a nice web page isn't being in business.

I'd like to know of other vendors in the continental US who are conversant with this process, as opposed to a general EV shop that has seen the pictures and thinks it looks easy. If I'm paying for someone to do the work, I'd prefer they broke other people's hardware first, to acquire the knowledge of how to not break mine. BTDT.

I'd sure like to know how to buy that "Made in USA" Tesla-branded seal.