I thought I should post an update. I havent in a bit.

I currently have 3 projects that I have been working on. I had to finally focus on one because they are each pretty expensive endeavors. Here are my 3 projects.

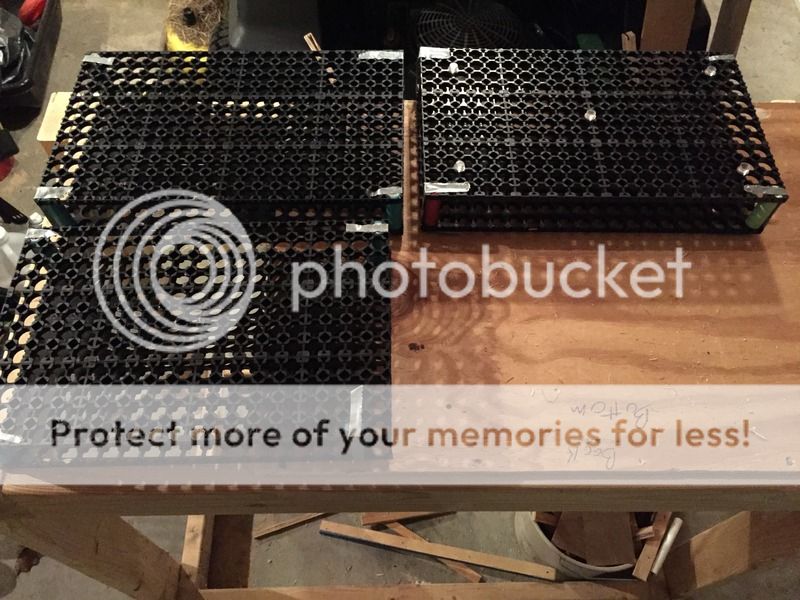

1. As this thread shows, I want to add an additional battery pack to my Rav. Unless more suitable batteries fall into my lap, I am going to use 18650 cells and put them together into modules. I found two suppliers. I can get recycled cells that are 2000-2800 mah for a $1 each, or $3,680. OR 3500 mah LG MJ1 cells for $3.80 each. Its a great deal but it would take 2-3 months for them to be shipped overseas. The total would be about $14,000! Its a lot of capacity but thats a lot of money.

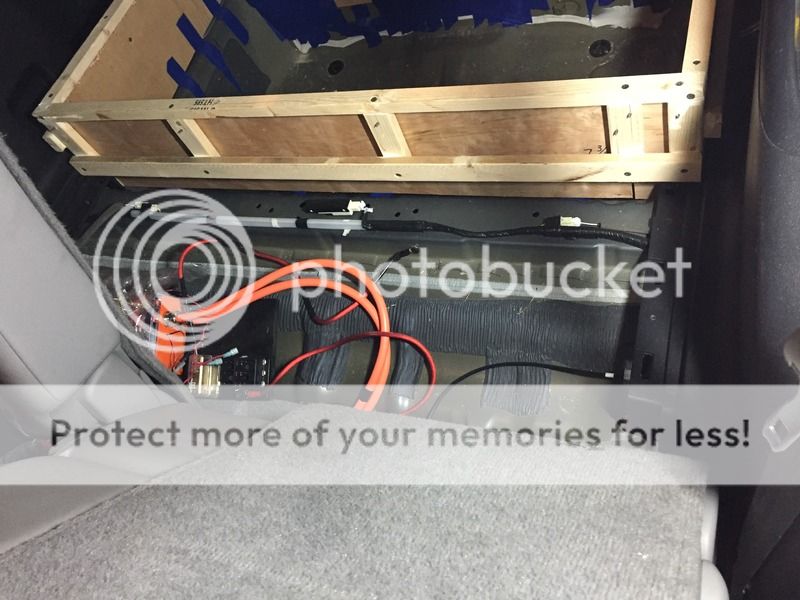

2. I want to build a range extending battery trailer. As you might have seen on facebook, I found a working Rav pack. With the help of Matt, another member here, we are going to build a controller for it. He is fluent in CAN BUS which I am not. He has made a lot of progress already. We should have a controller soon. Everything else is ready. I have all of the connections, wire and trailer. For that reason I decided to complete project 2 first. I am basically there.

2 1/2. Currently the range extending trailer R.E.T. will be made using the Rav pack. However I am keeping my eyes open for a Tesla 85 or 100 kw pack. I hope to do the same thing but with a Tesla pack. Potentially tripling my range!

2 3/4. Once I get a Tesla R.E.T. I have a long term goal of building a teardrop trailer that I can bolt on and off as needed. My wife and I love road trips and I really like the idea of pulling a small camper for a long road trip. I plan on building everything as lightweight as possible. Aluminum frame trailer, fiberglass teardrop shell, aluminum teardrop frame and as few as amenities as the wife will tolerate.

3. I figure if someone at some point wants to buy my Rav4 EV modules, I will keep the battery shell and stuff it full of 100kw Tesla modules. I took apart the pack and measured everything. I can fit 15 Tesla 100kw modules. That would be 90s instead of our 92s but it might be ok. Again, because I dont speak CAN I would have to rely on help from others. I am trying to learn but it just isnt my thing. Not to mention that it requires some pretty expensive equipment to dive in and test with. Regardless, if I can get help, I can make 15 modules fit. I just dont know what the Tesla and Toyota components would do when it saw power coming from a different pack. No idea. Also worth noting, it would require a 3 inch spacer in order to make room for a third level of modules. Currently the pack has 2 levels. It would mean that the pack would sit lower, closer to the ground. I dont think that in and of itself is an issue but I would probably want to make a couple fiberglass aero panels to fix aerodynamics under the car.

So thats where I am at now. Trailer is almost done and I am keeping an eye out for a Tesla pack. I just finished the fiberglass onboard battery box so that is still progressing too. I have to go put my kid to bed but Ill try to get some photos up tonight. In the meantime, you can check out my youtube page. Warning though, it sucks and I'm sure I sound like an *****. haha

https://www.youtube.com/user/jimbo69ny

![Car Charger Adapter - [Upgraded Version] Car Fast Charger with 4 Ports (PD+QC3.0+USB C) Atmosphere Light - 12-24V Car Truck SUV Universal USB Cigarette Lighter Adapter(QC3.0+PD+2.4A+2.4A)](https://m.media-amazon.com/images/I/41TzjUqcNaL._SL500_.jpg)