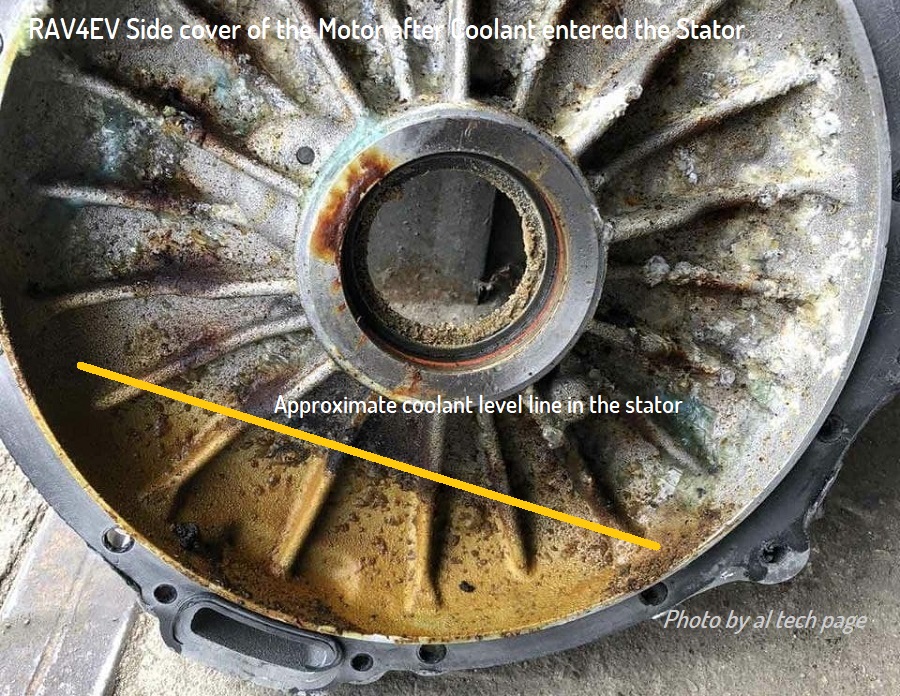

"The same place" the coolant came is is the seal you just removed, and once it got past the seal, it was aerosolized (I do like that word) and migrates through that reluctor chamber vent hole, from whence it won't come back. To remove any moisture on the other side of that vent, the rotor end cap has to be removed, and the rotor removed.

I did that job for the same reason as yours: I had coolant leakage on my Reman LDU and while I didn't have a vent hole like yours, still there was plenty of coolant on the stator side of that cap.

There is a case vent and a gearbox vent, both on top near the center, but they only equalize pressure due to the inverter heating up, and they incorporate a teflon composite filter (sort of a mesh) that's specifically designed to prevent water getting through. Water that's in there is going to stay in there.

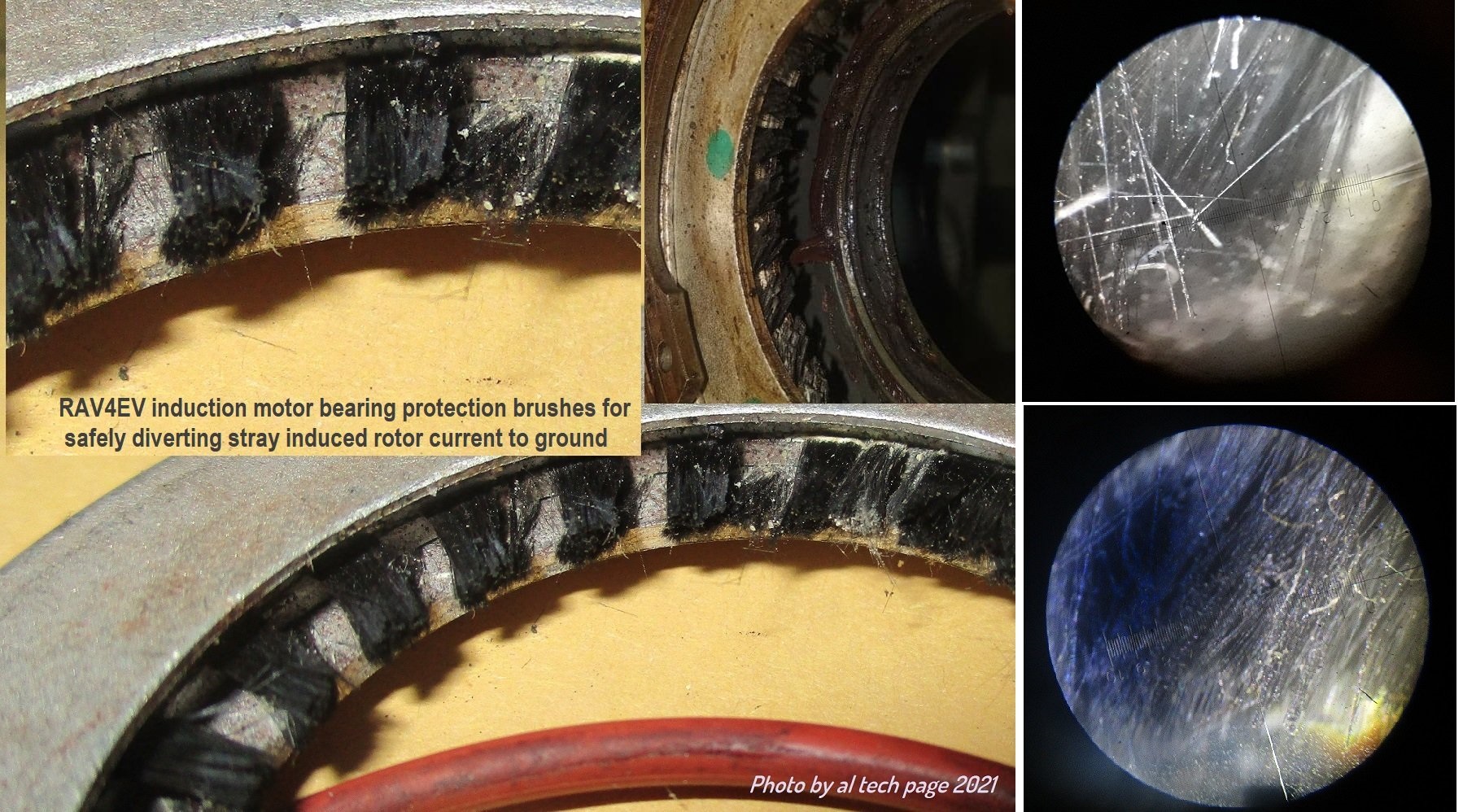

If you weren't hearing anything unusual before, and you've owned it long enough to know what it sounded like some miles ago, then the bearing is possibly OK for now. If it's never been touched, it'll have the original steel balls in the bearing and the ill-fated Aegis ring that didn't work for long, so at some point you'll have to replace both of the rotor bearings for the later (and more expensive) hybrid ceramic ball beaings . . . which moves the problem downstream to the pinion bearings and gears, but they seem to tolerate it better, or at least longer.

If you disassemble the LDU to remove the rotor and clean out the stator cavity, I recommend replacing the rotor's bearings; that's best practice. Esp. if you see an old Aegis ring inside when you remove the rotor.

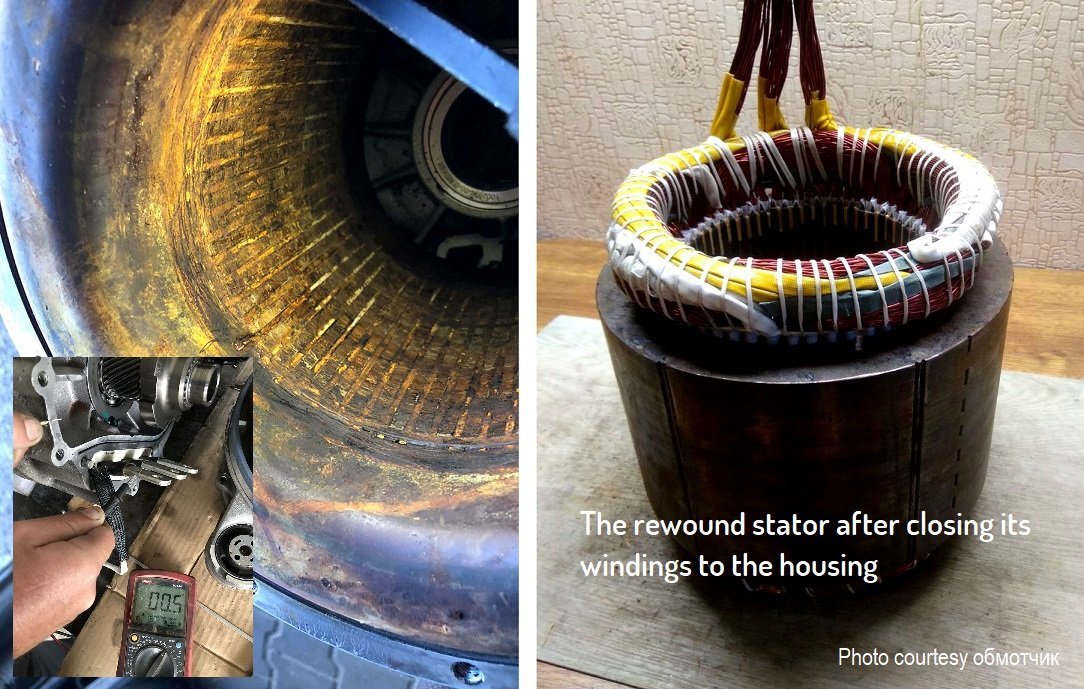

The stator's HV windings isolation resistance goes down when exposed to water, and it gets worse. When it gets low enough, the BMS check at startup will fail, and it won't allow the contactors to close. Then you have to have the stator dried out by ReVolt in Arizona, and if they can dry out your stator, you're probably out around $4-8k. Plus R&R of the LDU, of course. Until recently, there was nobody advertising that they could dry out damaged stators, but ReVolt says they can now -- there's a lot more demand from Tesla MS/X owners recently